Page 36 - Master Catalog 2017, Inch

P. 36

™

WIDIA Victory • High-Performance Inserts

™

High-Temp Alloys • Iron-, Cobalt-, and Nickel-Based and Titanium Alloys

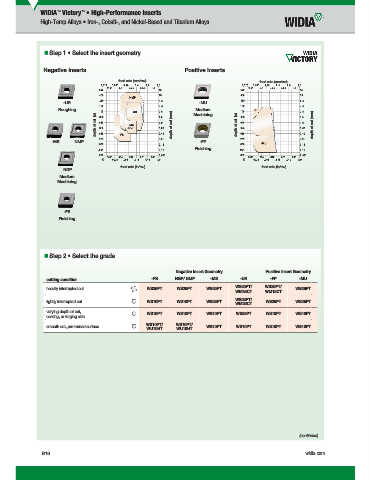

Step 1 • Select the insert geometry

Negative Inserts Positive Inserts

feed rate (mm/rev) feed rate (mm/rev)

-UR -MU

Medium

Roughing Machining

depth of cut (in) depth of cut (mm) depth of cut (in) depth of cut (mm)

-MS .NMP -FP

Finishing

feed rate (in/rev) feed rate (in/rev)

.NGP

Medium

Machining

-FS

Finishing

Step 2 • Select the grade

Negative Insert Geometry Positive Insert Geometry

cutting condition -FS .NGP/.NMP -MS -UR -FP -MU

WS25PT/ WS25PT/

heavily interrupted cut WS25PT WS25PT WS25PT WS25PT

WM35CT WM15CT

WS25PT/

lightly interrupted cut WS10PT WS10PT WS25PT WS25PT WS25PT

WM25CT

varying depth of cut, WS10PT WS10PT WS10PT WS25PT WS10PT WS10PT

casting, or forging skin

WS10PT/ WS10PT/

smooth cut, pre-turned surface WS10PT WS10PT WS10PT WS10PT

WU10HT WU10HT

(continued)

B16 widia.com

16 T

i

i

WID M

V

B016 B017 Mi

I

L WID_Master16_Turning_Inserts_B016_B017_Minch_REBRAND.indd 16 h REBRAND N b 9 2015 10 32 AM 11/10/15 11:01 AM