Page 413 - Master Catalog 2017, Inch

P. 413

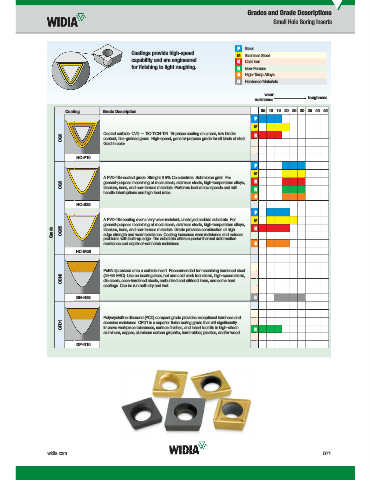

Grades and Grade Descriptions

Small Hole Boring Inserts

P Steel

Coatings provide high-speed

M Stainless Steel

capability and are engineered

K Cast Iron

for finishing to light roughing. N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear toughness

resistance

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

M

Coated carbide. CVD — TiC-TiCN-TiN. Tri-phase coating on a hard, low binder K

CG6 content, fi ne-grained grade. High-speed, general-purpose grade for all kinds of steel.

Gold in color.

HC-P10

P

M

A PVD-TiN-coated grade. Straight 9.5% Co substrate. Submicron grain. For

CG5 general-purpose machining of most steels, stainless steels, high-temperature alloys, K

titanium, irons, and non-ferrous materials. Performs best at low speeds and will

handle interruptions and high feed rates. N

S

HC-S25

P

A PVD-TiN coating over a very wear-resistant, unalloyed carbide substrate. For M

general-purpose machining of most steels, stainless steels, high-temperature alloys,

Grade CG55 titanium, irons, and non-ferrous materials. Grade provides combination of high K

edge strength and wear resistance. Coating increases wear resistance and reduces

problems with built-up edge. The substrate offers superior thermal deformation

resistance and depth-of-cut notch resistance. S

HC-M20

PcBN tip brazed onto a carbide insert. Recommended for machining hardened steel

CBN6 (45–65 HRC). Use on bearing steel, hot and cold work tool steels, high-speed steels,

die steels, case-hardened steels, carburized and nitrided irons, and some hard

coatings. Can be run both dry and wet.

BN-H25 H

Polycrystalline diamond (PCD) compact grade provides exceptional hardness and

CPD1 abrasion resistance. CPD1 is a superior fi nish boring grade that will signifi cantly

improve workpiece tolerances, surface fi nishes, and insert tool life in high-silicon

aluminum, copper, aluminum carbon graphite, hard rubber, plastics, and/or wood. N

DP-N10

widia.com D71

10/30/15 2:00 PM

WID_Master16_Turning_Circle_D070_D071_Minch_REBRAND.indd 71 L V i WID M 16 T i Ci l D070 D071 Mi h REBRANDO b 152015758AM