Page 521 - Master Catalog 2017, Inch

P. 521

TopGroove

™

Grades and Grade Descriptions

P Steel

Coatings provide high-speed Stainless Steel

M

capability and are engineered

K Cast Iron

for finishing to heavy roughing.

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear toughness

resistance

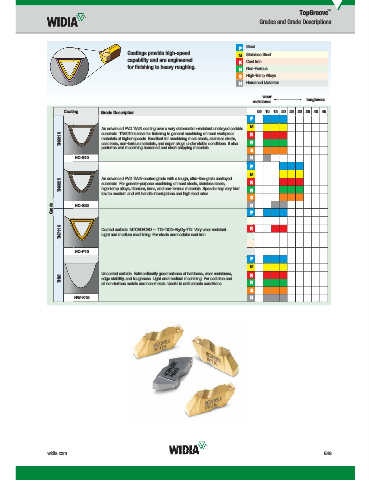

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

An advanced PVD TiAlN coating over a very deformation-resistant unalloyed carbide M

TN6010 materials at higher speeds. Excellent for machining most steels, stainless steels, K

substrate. TN6010 is ideal for fi nishing to general machining of most workpiece

N

cast irons, non-ferrous materials, and super alloys under stable conditions. It also

performs well machining hardened and short chipping materials.

S

HC-S10 H

P

M

An advanced PVD TiAlN-coated grade with a tough, ultra-fi ne-grain unalloyed

TN6025 substrate. For general-purpose machining of most steels, stainless steels, K

high-temp alloys, titanium, irons, and non-ferrous materials. Speeds may vary from

low to medium and will handle interruptions and high feed rates. N

S

Grade HC-S25 H

P

TN7110 Coated carbide. MTCVD/CVD — TiN-TiCN-Al O -TiN. Very wear resistant. K

2 3

Light and medium machining. For steels and nodular cast iron.

HC-P10

P

M

Uncoated carbide. Extraordinarily good balance of hardness, wear resistance, K

THM edge stability, and toughness. Light and medium machining. For cast iron and

all non-ferrous metals and non-metals. Useful in unfavorable conditions. N

S

HW-K15 H

widia.com E49

WID_Master16_Turning_Grooving&CutOff_E048_E049_Minch_REBRAND.indd 49 L V i WID M 16 T i G i &C Off E048 E049 Mi h REBRANDO b 152015813AM

10/30/15 2:05 PM