Page 571 - Master Catalog 2017, Inch

P. 571

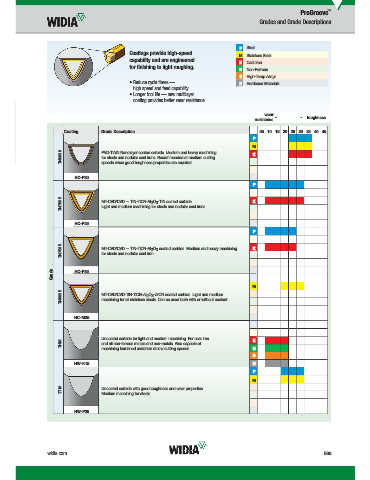

ProGroove

™

Grades and Grade Descriptions

P Steel

Coatings provide high-speed M Stainless Steel

capability and are engineered

K Cast Iron

for finishing to light roughing.

N Non-Ferrous

S High-Temp Alloys

• Reduce cycle times — H Hardened Materials

high speed and feed capability.

• Longer tool life — new multilayer

coating provides better wear resistance.

wear

toughness

resistance

Coating Grade Description 05 10 15 20 25 30 35 40 45

P

M

TN6030 PVD-TiAlN Nanolayer coated carbide. Medium and heavy machining K

for steels and nodular cast irons. Recommended at medium cutting

speeds when good toughness properties are required.

HC-P30

P

TN7525 MT-CVD/CVD — TiN-TiCN-Al O -TiN coated carbide. K

2 3

Light and medium machining for steels and nodular cast irons.

HC-P25

P

TN7535 MT-CVD/CVD — TiN-TiCN-Al O coated carbide. Medium and heavy machining K

2 3

for steels and nodular cast iron.

Grade HC-P35

M

TN8025 MT-CVD/CVD-TiN-TiCN-Al O -ZrCN coated carbide. Light and medium

2 3

machining for all stainless steels. Can be used both with or without coolant.

HC-M25

Uncoated carbide for light and medium machining. For cast iron K

THM and all non-ferrous metals and non-metals. Also capable of

machining hardened materials at low cutting speeds. N

S

HW-K15 H

P

M

TTM Uncoated carbide with good toughness and wear properties.

Medium machining for steels.

HW-P25

widia.com E99

b 92015320PM

WID_Master16_Turning_Grooving&CutOff_E098_E099_Minch_REBRAND.indd 99 L V i WID M 16 T i G i &C Off E098 E099 Mi h REBRANDN 11/10/15 11:14 AM