Page 618 - Master Catalog 2017, Inch

P. 618

™

Ranger

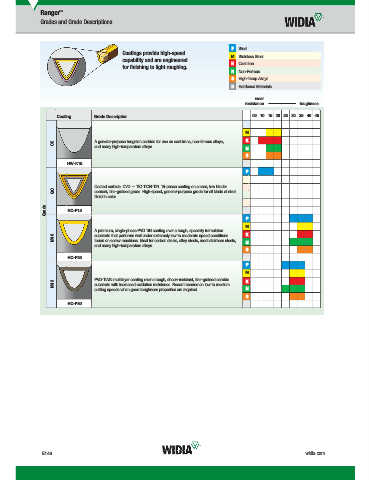

Grades and Grade Descriptions

P Steel

Coatings provide high-speed

M Stainless Steel

capability and are engineered K Cast Iron

for finishing to light roughing.

N Non-Ferrous

S High-Temp Alloys

H Hardened Materials

wear

resistance toughness

Coating Grade Description 05 10 15 20 25 30 35 40 45

M

C2 A general-purpose tungsten carbide for use on cast irons, non-ferrous alloys, K

and many high-temperature alloys.

N

S

HW-K15

P

Coated carbide. CVD — TiC-TiCN-TiN. Tri-phase coating on a hard, low binder

GC content, fi ne-grained grade. High-speed, general-purpose grade for all kinds of steel.

Gold in color.

Grade HC-P15

P

M

A premium, single-phase PVD TiN coating over a tough, specially formulated

M40 substrate that performs well under extremely low to moderate speed conditions K

found on screw machines. Ideal for carbon steels, alloy steels, most stainless steels,

and many high-temperature alloys. N

S

HC-P35

P

M

PVD-TiAlN multilayer coating over a tough, shock-resistant, fi ne-grained carbide K

M43 substrate with increased oxidation resistance. Recommended on low to medium

cutting speeds when good toughness properties are required. N

S

HC-P30

E146 widia.com

i

V

&C Off E146 E147 Mi

WID M

G

i

i

16 T

L WID_Master16_Turning_Grooving&CutOff_E146_E147_Minch_REBRAND.indd 146 h REBRANDO b 15 20158 28AM 10/30/15 2:08 PM