Page 945 - Master Catalog 2017, Inch

P. 945

™

Copy Mills • M200 Series

Recommended Starting Feeds

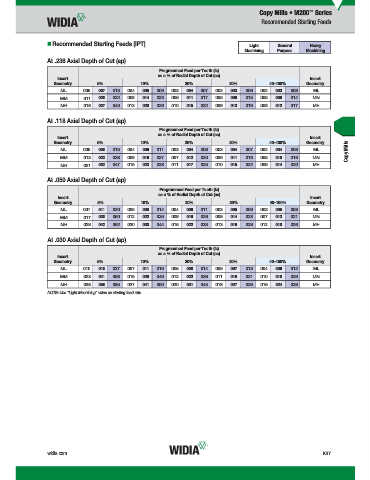

Recommended Starting Feeds [IPT] Light General Heavy

Machining Purpose Machining

At .236 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

ML .005 .007 .013 .004 .005 .009 .003 .004 .007 .002 .003 .006 .002 .003 .006 ML

MM .011 .020 .032 .008 .014 .023 .006 .011 .017 .005 .009 .015 .005 .009 .014 MM

MH .018 .027 .040 .013 .020 .029 .010 .015 .022 .009 .013 .019 .008 .012 .017 MH

At .118 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

Copy Mills

ML .006 .008 .015 .004 .006 .011 .003 .004 .008 .003 .004 .007 .002 .004 .006 ML

MM .013 .023 .038 .009 .016 .027 .007 .012 .020 .006 .011 .018 .005 .010 .016 MM

MH .021 .032 .047 .015 .023 .033 .011 .017 .025 .010 .015 .022 .009 .014 .020 MH

At .059 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

ML .007 .011 .020 .005 .008 .014 .004 .006 .011 .003 .005 .009 .003 .005 .008 ML

MM .017 .030 .050 .012 .022 .035 .009 .016 .026 .008 .014 .023 .007 .013 .021 MM

MH .028 .042 .062 .020 .030 .044 .015 .022 .033 .013 .019 .028 .012 .018 .026 MH

At .030 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

ML .010 .015 .027 .007 .011 .019 .005 .008 .014 .005 .007 .013 .004 .006 .012 ML

MM .023 .041 .068 .016 .029 .049 .012 .022 .036 .011 .019 .031 .010 .018 .029 MM

MH .038 .058 .085 .027 .041 .060 .020 .031 .045 .018 .027 .039 .016 .024 .036 MH

NOTE: Use “Light Machining” value as starting feed rate.

widia.com K37

WID_Master16_IndexableMIlling_CopyMills_K036_K037_Minch_REBRAND.indd 37 L V i WID M 16 I d bl MIlli C Mill K036 K037 Mi h REBRANDO b 1420151143AM

10/29/15 1:40 PM