Page 504 - APEX MRO Products

P. 504

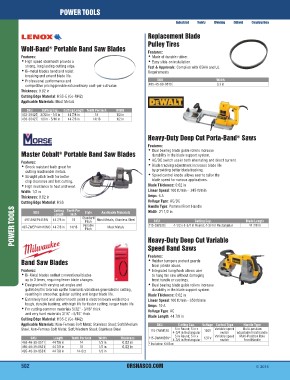

POWER TOOLS

Industrial Safety Welding Oilfield Construction

Wolf-Band® Portable Band Saw Blades Replacement Blade

F•eaHtiugrhessp: eed steel teeth provide a Pulley Tires

strong, long lasting cutting edge. Features:

• Bi‑metal blades bend and resist • Made of durable rubber.

• Easy slide‑on installation.

breaking and extend blade life.

Test & Approvals: Complies with OSHA and UL

• Professional performance and Requirements

competitive pricing provide extraordinary cost‑per‑cut value. SKU Width

Thickness: 0.02 in 495‑45‑69‑0010 0.3 in

Cutting Edge Material: HSS‑E (Co‑M42)

Applicable Materials: Most Metals

SKU Cutting Cap. Cutting Length Teeth Per Inch Width

1/2 in

433‑38425 3/32 in ‑ 1/4 in 44 7/8 in 18 1/2 in

433‑38427 1/8 in ‑ 5/16 in 44 7/8 in 14/18

Master Cobalt® Portable Band Saw Blades Heavy-Duty Deep Cut Porta-Band® Saws

F•eaSthuorceks:resistant teeth great for •FeaDtuuarlebse: aring blade guide rollers increase

cutting machinable metals. durability in the blade support system.

• Straight pitch teeth for better • AC/DC switch use in both alternating and direct current.

• Blade tracking adjustment increases blade life

chip clearance and fast cutting.

by providing better blade tracking.

• High resistance to heat and wear.

• Speed control knobs allows user to tailor the

Width: 1/2 in

Thickness: 0.02 in blade speed for various applications.

Cutting Edge Material: HSS Blade Thickness: 0.02 in

Linear Speed: 100 ft/min ‑ 245 ft/min

POWER TOOLS SKU Cutting Teeth Per Style Applicable Materials Amps: 6 A

Length Inch Voltage Type: AC/DC

Handle Type: Pommel Front Handle

Width: 21 1/2 in

497‑ZWEP4418W 44 7/8 in 18 Standard Most Metals; Stainless Steel SKU Cutting Cap. Blade Length

Pitch 115‑DW328 4‑1/2 x 4‑3/4 in Round; 4‑3/4 in Rectangular 44 7/8 in

Variable

497‑ZWEP441418MC 44 7/8 in 14/18 Pitch Most Metals

Band Saw Blades Heavy-Duty Deep Cut Variable

•FeaBtiu‑Mreest:al blades outlast conventional blades Speed Band Saws

up to 3 times, requiring fewer blade changes. Features:

• Designed with varying set angles and • Rubber bumpers protect guards

gullet depths to break up the harmonic vibrations generated in cutting, from jobsite abuse.

resulting in smoother, quieter cutting and longer blade life.

• Integrated hang hook allows user

• Extremely hard and uniform tooth point is electron beam welded to a

to hang the saw without damaging

tough, durable backing, with high life for faster cutting, longer blade life. front handle or castings.

• For cutting common materials 5/32” ‑ 3/16” thick • Dual bearing blade guide rollers increase

and very hard materials 3/16” ‑ 5/16” thick. durability in the blade support system.

Cutting Edge Material: HSS‑E (Co‑M42) Blade Thickness: 0.02 in

Applicable Materials: Non‑Ferrous Soft Metal; Stainless Steel; Soft/Medium Linear Speed: 100 ft/min ‑ 350 ft/min

Steel; Non‑Ferrous Soft Metal; Soft/Medium Steel; Stainless Steel Amps: 10 A

Voltage Type: AC

Blade Length: 44 7/8 in

SKU Cutting Cap. Voltage Control Type Handle Type

5 in Round; 5 in x Variable speed Multi‑position

115‑DWM120 4‑3/4 in Rectangular 120V switch adjustable front handle

SKU Length Teeth Per Inch Width Thickness 115‑DWM120K* 5 in Round; 5 in x 120 V Variable speed Multi‑Position Bale

495‑48‑39‑0511 44 7/8 in 14 1/2 in 0.02 in 4‑3/4 in Rectangular switch Front Handle

495‑48‑39‑0521 44 7/8 in 18 1/2 in 0.02 in * Includes: Kit Box

495‑48‑39‑0551 44 7/8 in 1/2 in

14‑Oct

502 ORSNASCO.COM © 2016