Page 51 - NEW Armstrong Book - 2

P. 51

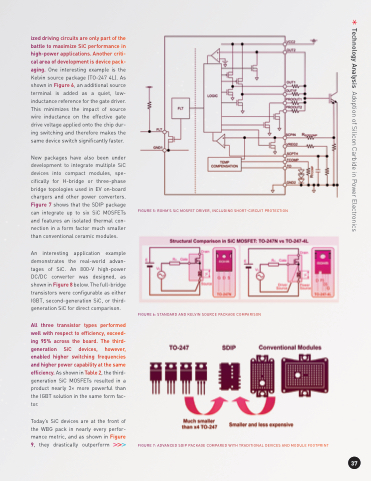

ized driving circuits are only part of the battle to maximize SiC performance in high-power applications. Another criti- cal area of development is device pack- aging. One interesting example is the Kelvin source package (TO-247 4L). As shown in Figure 6, an additional source terminal is added as a quiet, low- inductance reference for the gate driver. This minimizes the impact of source wire inductance on the effective gate drive voltage applied onto the chip dur- ing switching and therefore makes the same device switch significantly faster.

New packages have also been under development to integrate multiple SiC devices into compact modules, spe- cifically for H-bridge or three-phase bridge topologies used in EV on-board chargers and other power converters. Figure 7 shows that the SDIP package can integrate up to six SiC MOSFETs and features an isolated thermal con- nection in a form factor much smaller than conventional ceramic modules.

An interesting application example demonstrates the real-world advan- tages of SiC. An 800-V high-power DC/DC converter was designed, as shown in Figure 8 below. The full-bridge transistors were configurable as either IGBT, second-generation SiC, or third- generation SiC for direct comparison.

All three transistor types performed well with respect to efficiency, exceed- ing 95% across the board. The third- generation SiC devices, however, enabled higher switching frequencies and higher power capability at the same efficiency. As shown in Table 2, the third- generation SiC MOSFETs resulted in a product nearly 3× more powerful than the IGBT solution in the same form fac- tor.

Today’s SiC devices are at the front of the WBG pack in nearly every perfor- mance metric, and as shown in Figure 9, they drastically outperform

FIGURE 5: ROHM’S SiC MOSFET DRIVER, INCLUDING SHORT-CIRCUIT PROTECTION

FIGURE 6: STANDARD AND KELVIN SOURCE PACKAGE COMPARISON

FIGURE 7: ADVANCED SDIP PACKAGE COMPARED WITH TRADITIONAL DEVICES AND MODULE FOOTPRINT

37

Technology Analysis Adoption of Silicon Carbide in Power Electronics