Page 49 - NEW Armstrong Book - 2

P. 49

barrier diodes (SBDs), JFETs, PIN diodes, and MOSFETs. SBDs initially led the commercialization effort for SiC and found niche applications in power supply and protection circuits. The real game-changer for SiC was the devel- opment and mass production of the first MOSFETs based on the technol- ogy in 2010. Combined with the growing demand for high-power DC/DC convert- ers and motor drives in electric vehi- cles (EVs), the SiC MOSFET was well- positioned to take over a sizable share of the market.

EVs paved the way

for SiC

The development of high-quality SiC devices, particularly SBDs and MOSFETs, could have been seen as putting the proverbial cart before the horse. While there had been market demand from power delivery systems and solar energy conversion, it was truly the widespread adoption of the EV that created the greatest pull for SiC. This is because EVs place enormous demand on high-performance and high-power electronics in numerous systems simultaneously.

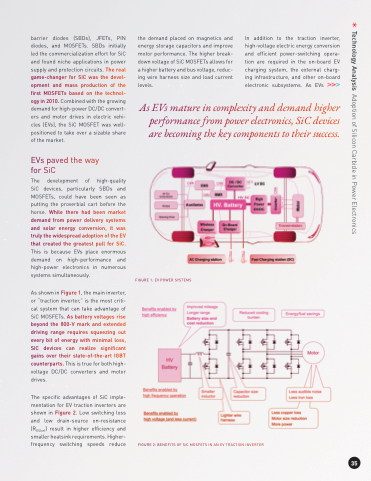

As shown in Figure 1, the main inverter, or “traction inverter,” is the most criti- cal system that can take advantage of SiC MOSFETs. As battery voltages rise beyond the 800-V mark and extended driving range requires squeezing out every bit of energy with minimal loss, SiC devices can realize significant gains over their state-of-the-art IGBT counterparts. This is true for both high- voltage DC/DC converters and motor drives.

The specific advantages of SiC imple- mentation for EV traction inverters are shown in Figure 2. Low switching loss and low drain-source on-resistance (RDS(on)) result in higher efficiency and smaller heatsink requirements. Higher- frequency switching speeds reduce

the demand placed on magnetics and energy storage capacitors and improve motor performance. The higher break- down voltage of SiC MOSFETs allows for a higher battery and bus voltage, reduc- ing wire harness size and load current levels.

In addition to the traction inverter, high-voltage electric energy conversion and efficient power-switching opera- tion are required in the on-board EV charging system, the external charg- ing infrastructure, and other on-board electronic subsystems. As EVs

As EVs mature in complexity and demand higher performance from power electronics, SiC devices are becoming the key components to their success.

FIGURE 1: EV POWER SYSTEMS

FIGURE 2: BENEFITS OF SiC MOSFETS IN AN EV TRACTION INVERTER

35

Technology Analysis Adoption of Silicon Carbide in Power Electronics