Page 48 - NEW Armstrong Book - 2

P. 48

34

ASPENCORE GUIDE TO SILICON CARBIDE

Adoption of Silicon Carbide

in Power Electronics

in the “off” state. Many wide-bandgap (WBG) materials offer the highest per- formance in these two states. They have typically been fabricated from com- pounds of group III-V and II-VI elements of the periodic table. For example, gal- lium nitride has a bandgap of 3.44 eV, and zinc oxide has a bandgap of 3.37 eV. In the carbon group, IV, however, there

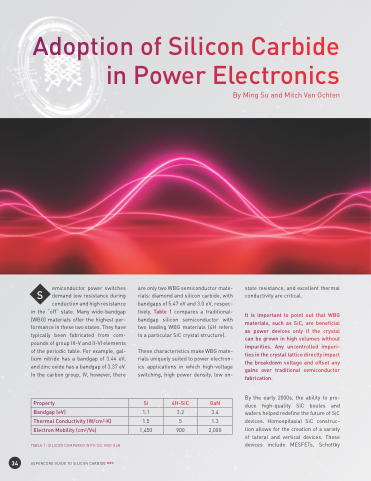

TABLE 1: SILICON COMPARED WITH SiC AND GaN

By Ming Su and Mitch Van Ochten

S

emiconductor power switches demand low resistance during conduction and high resistance

are only two WBG semiconductor mate- rials: diamond and silicon carbide, with bandgaps of 5.47 eV and 3.0 eV, respec- tively. Table 1 compares a traditional- bandgap silicon semiconductor with two leading WBG materials (4H refers to a particular SiC crystal structure).

These characteristics make WBG mate- rials uniquely suited to power electron- ics applications in which high-voltage switching, high power density, low on-

state resistance, and excellent thermal conductivity are critical.

It is important to point out that WBG materials, such as SiC, are beneficial as power devices only if the crystal can be grown in high volumes without impurities. Any uncontrolled impuri- ties in the crystal lattice directly impact the breakdown voltage and offset any gains over traditional semiconductor fabrication.

By the early 2000s, the ability to pro- duce high-quality SiC boules and wafers helped redefine the future of SiC devices. Homoepitaxial SiC construc- tion allows for the creation of a variety of lateral and vertical devices. These devices include MESFETs, Schottky

Property

Si

4H-SiC

GaN

Bandgap (eV)

1.1

3.2

3.4

Thermal Conductivity (W/cm2·K)

1.5

5

1.3

Electron Mobility (cm2/Vs)

1,450

900

2,000