Page 29 - Roisin McGrath

P. 29

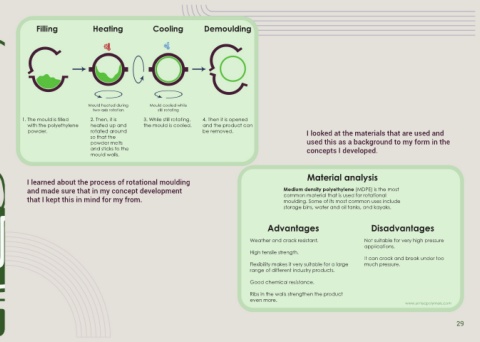

Filling Heating Cooling Demoulding

Mould heated during Mould cooled while

two-axis rotation still rotating

1. The mould is filled 2. Then, it is 3. While still rotating, 4. Then it is opened

with the polyethylene heated up and the mould is cooled. and the product can

powder. rotated around be removed. I looked at the materials that are used and

so that the

powder melts used this as a background to my form in the

and sticks to the concepts I developed.

mould walls.

Material analysis

I learned about the process of rotational moulding

and made sure that in my concept development Medium density polyethylene (MDPE) is the most

that I kept this in mind for my from. common material that is used for rotational

moulding. Some of its most common uses include

storage bins, water and oil tanks, and kayaks.

Advantages Disadvantages

Weather and crack resistant. Not suitable for very high pressure

applications.

High tensile strength.

It can crack and break under too

Flexibility makes it very suitable for a large much pressure.

range of different industry products.

Good chemical resistance.

Ribs in the walls strengthen the product

even more.

www.entecpolymers.com

29