Page 33 - Emily

P. 33

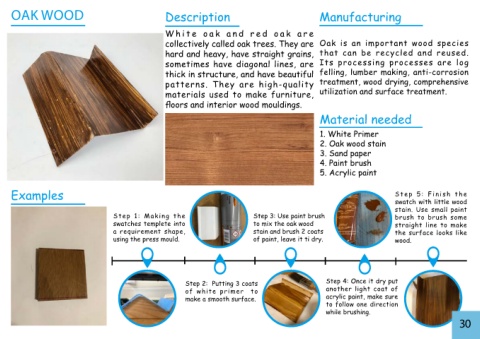

RUBBER Description Manufacturing OAK WOOD Description Manufacturing

Rubber refers to a highly elastic It is a material that is elastic, insulating, W hite oak and red oak are

polymer material with reversible impermeable to water and air by collectively called oak trees. They are Oak is an important wood species

deformation. It is elastic at room extracting the latex of rubber trees, hard and heavy, have straight grains, that can be recycled and reused.

temperature and can produce greater rubber grass and other plants. Natural sometimes have diagonal lines, are Its processing processes are log

deformation under a small external rubber is processed by extracting gum thick in structure, and have beautiful felling, lumber making, anti-corrosion

from rubber trees, rubber grass and

force. It can be restored to its other plants; synthetic rubber is obtained patterns. They are high-quality treatment, wood drying, comprehensive

original state after the external by polymerization of various monomers. materials used to make furniture, utilization and surface treatment.

force is removed. Rubber products are widely used in all floors and interior wood mouldings.

aspects of industry or life. Material needed

Material needed 1. White Primer

2. Oak wood stain

1. White primer

2 Sand paper 3. Sand paper

3. Black spray paint 4. Paint brush

4. Scraper 5. Acrylic paint

5. Sanitary Silicone

Examples Examples Step 5: Finish the

swatch with little wood

stain. Use small paint

Step 1: Making the Step 3: Mix the slicone Step 5: Give the swatch Step 1: Making the Step 3: Use paint brush brush to brush some

swatches templete into with black spray paint a very light sanding swatches templete into to mix the oak wood straight line to make

a requirement shape, and to brush thrm on with wet sandpaper and a requirement shape, stain and brush 2 coats the surface looks like

using the press mould. the swatch wait it to dry. using the press mould. of paint, leave it ti dry. wood.

Step 2: Putting 3 coats Step 4: Use a scraper Step 4: Once it dry put

of white primer to to brush the surface to Step 2: Putting 3 coats another light coat of

make a smooth surface. male a flat finish. Wait of white primer to acrylic paint, make sure

it to dry. make a smooth surface. to follow one direction

while brushing.

29 30