Page 88 - Ken O Brien

P. 88

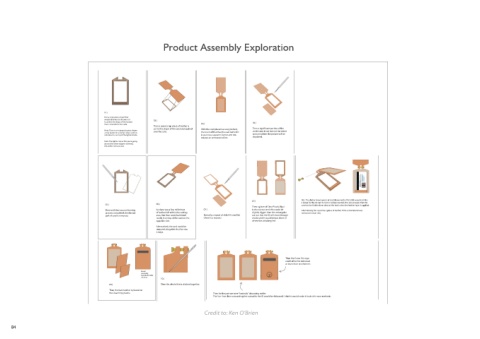

Product Assembly Exploration

01.)

First a scrap piece of card that

would otherwise be thrown out 02.)

is cut into the shape of the lanyard 04.)

that is intended to be made. 03.)

Then a spare scrap piece of leather is

cut to the shape of the card and applied With the card placed securely behind,

Note: There is a rectangular piece shown centre area is cut but not the entire

at the bottom in a darker colour and this over the card. the one half that has the card behind it amount where the picture will be

indicates it is on top of the lighter shade. is put into a vacumn former and this

displated.

Note: The lighter colour thin piece going

around the entire shape is recessed,

this will be relevant later

07.) a ledge for the ID card to rest on when inserted, this also ensures that the

05.) 06.) card can be hidden from view at the back when the leather layer is applied.

Then a piece of Clear Plastic Vinyl

Then with the vacumn forming As there was a few millimitres 07.) is also cut out and this would be Alternatively this could be a piece of leather if the card material was

process completed, the thinner of leather left within the cutting slightly bigger than the rectangular removed in slide 06.).

part of card is removed. area, this then could be folded Basically a repeat of slide 04.) and 06.) cut out that the ID will show through

neatly in on top of the card on the (there is a reason.) and its width would be just short of

opposite side. where the sititching line

Alternatively the card could be

removed altogether but for now

it stays.

Then the Carve On Logo

could either be debossed

or lasered on or whatever.

Would

eventually

look like this after

stitching.

10.)

09.) Then the whole this is stitched together.

Then the back leather is placed on

the Clear Vinyl plastic. Then for the part we were “heatedly” discussing earlier.

The 3 or 4mm line surrounding the cutout for the ID would be debossed. I think it would make it look a bit more aesthetic.

84