Page 3 - Roma_Spec_v2

P. 3

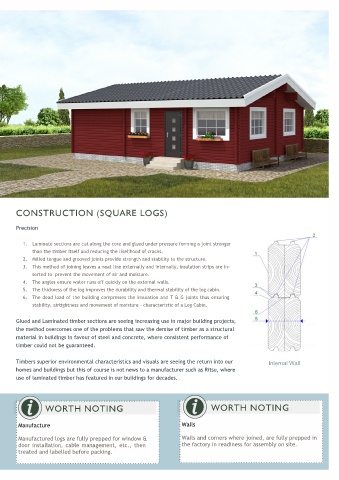

CONSTRUCTION (SQUARE LOGS)

Precision

1. Laminate sections are cut along the core and glued under pressure forming a joint stronger

than the timber itself and reducing the likelihood of cracks.

2. Milled tongue and grooved joints provide strength and stability to the structure.

3. This method of joining leaves a neat line externally and internally, insulation strips are in-

serted to prevent the movement of air and moisture.

4. The angles ensure water runs off quickly on the external walls.

5. The thickness of the log improves the durability and thermal stability of the log cabin.

6. The dead load of the building compresses the insulation and T & G joints thus ensuring

stability, airtightness and movement of moisture - characteristic of a Log Cabin.

Glued and Laminated timber sections are seeing increasing use in major building projects,

the method overcomes one of the problems that saw the demise of timber as a structural

material in buildings in favour of steel and concrete, where consistent performance of

timber could not be guaranteed.

Timbers superior environmental characteristics and visuals are seeing the return into our Internal Wall

homes and buildings but this of course is not news to a manufacturer such as Ritsu, where

use of laminated timber has featured in our buildings for decades.

WORTH NOTING WORTH NOTING

Manufacture Walls

Manufactured logs are fully prepped for window & Walls and corners where joined, are fully prepped in

door installation, cable management, etc., then the factory in readiness for assembly on site.

treated and labelled before packing.