Page 20 - metal-experts-binder

P. 20

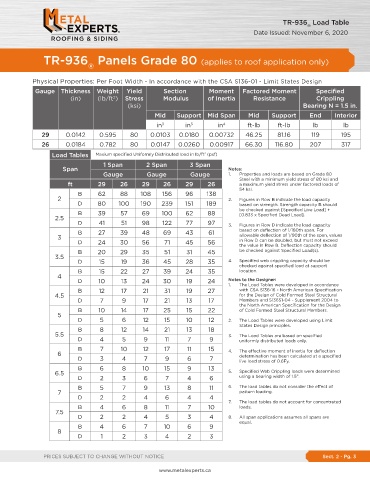

TR-936 Load Table

®

Date Issued: November 6, 2020

Scan QR Code to Open

Installation Instructions TR-936 Panels Grade 80 (applies to roof application only)

®

Physical Properties: Per Foot Width - In accordance with the CSA S136-01 - Limit States Design

Gauge Thickness Weight Yield Section Moment Factored Moment Specified

(in) (lb/ft ) Stress Modulus of Inertia Resistance Crippling

2

(ksi) Bearing N = 1.5 in.

Mid Support Mid Span Mid Support End Interior

in 3 in 3 in 4 ft-lb ft-lb lb lb

29 0.0142 0.595 80 0.0103 0.0180 0.00732 46.25 81.16 119 195

26 0.0184 0.782 80 0.0147 0.0260 0.00917 66.30 116.80 207 317

Load Tables Maxium specified Uniformly Distributed load in lb/ft (psf)

2

1 Span 2 Span 3 Span

Span Notes:

Gauge Gauge Gauge 1. Properties and loads are based on Grade 80

Steel with a minimum yield stress of 80 ksi and

ft 29 26 29 26 29 26 a maximum yield stress under factored loads of

54 ksi.

B 62 88 108 156 96 138

2 2. Figures in Row B indicate the load capacity

D 80 100 190 239 151 189 based on strength. Strength capacity B should

be checked against [Specified Live Load] +

B 39 57 69 100 62 88

2.5 [0.833 x Specified Dead Load].

D 41 51 98 122 77 97 3. Figures in Row D indicate the load capacity

B 27 39 48 69 43 61 based on deflection of 1/180th span. For

3 allowable deflection of 1/90th of the span, values

D 24 30 56 71 45 56 in Row D can be doubled, but must not exceed

the value in Row B. Deflection capacity should

B 20 29 35 51 31 45 be checked against Specified Load(s).

3.5

D 15 19 36 45 28 35 4. Specified web crippling capacity should be

checked against specified load at support

B 15 22 27 39 24 35 location.

4

D 10 13 24 30 19 24 Notes to the Designer:

1. The Load Tables were developed in accordance

B 12 17 21 31 19 27 with CSA S136-16 - North American Specification

4.5 for the Design of Cold Formed Steel Structural

D 7 9 17 21 13 17 Members and S136S1-04 - Supplement 2004 to

the North American Specification for the Design

B 10 14 17 25 15 22 of Cold Formed Steel Structural Members.

5

D 5 6 12 15 10 12 2. The Load Tables were developed using Limit

States Design principles.

B 8 12 14 21 13 18

5.5 3. The Load Tables are based on specified

D 4 5 9 11 7 9 uniformly distributed loads only.

B 7 10 12 17 11 15

6 4. The effective moment of inertia for deflection

D 3 4 7 9 6 7 determination has been calculated at a specified

live load stress of 0.6Fy.

B 6 8 10 15 9 13

6.5 5. Specified Web Crippling loads were determined

D 2 3 6 7 4 6 using a bearing width of 1.5”.

B 5 7 9 13 8 11 6. The load tables do not consider the effect of

7 pattern loading.

D 2 2 4 6 4 4

7. The load tables do not account for concentrated

B 4 6 8 11 7 10 loads.

7.5

D 2 2 4 5 3 4 8. All span applications assumes all spans are

equal.

B 4 6 7 10 6 9

8

D 1 2 3 4 2 3

PRICES SUBJECT TO CHANGE WITHOUT NOTICE Sect. 2 - Pg. 3

www.metalexperts.ca