Page 21 - DP Digital Sample

P. 21

innumerable clinical applications which are conservative.

METHODS TO ACHIEVE A BONDABLE SURFACE

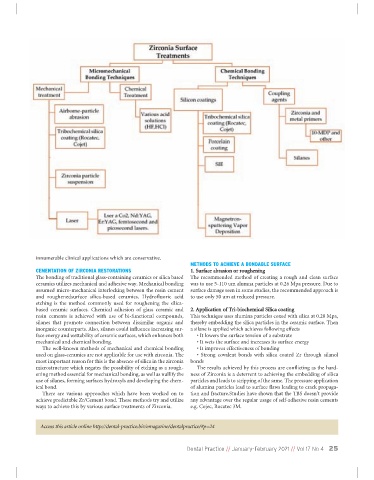

CEMENTATION OF ZIRCONIA RESTORATIONS 1. Surface abrasion or roughening

The bonding of traditional glass-containing ceramics or silica based The recommended method of creating a rough and clean surface

ceramics utilizes mechanical and adhesive way. Mechanical bonding was to use 5-110 um alumna particles at 0.26 Mpa pressure. Due to

assumed micro-mechanical interlocking between the resin cement surface damage seen in some studies, the recommended approach is

and roughenedsurface silica-based ceramics. Hydrofluoric acid to use only 50 um at reduced pressure.

etching is the method commonly used for roughening the silica-

based ceramic surfaces. Chemical adhesion of glass ceramic and 2. Application of Tri-biochemical Silica coating

resin cements is achieved with use of bi-functional compounds, This technique uses alumina particles coxed with silica at 0.28 Mpa,

silanes that promote connection between dissimilar organic and thereby embedding the silica particles in the ceramic surface. Then

inorganic counterparts. Also, silanes could influence increasing sur- a silane is applied which achieves following effects

face energy and wettability of ceramic surfaces, which enhances both • It lowers the surface tension of a substrate

mechanical and chemical bonding. • It wets the surface and increases its surface energy

The well-known methods of mechanical and chemical bonding • It improves effectiveness of bonding

used on glass-ceramics are not applicable for use with zirconia. The • Strong covalent bonds with silica coated Zr through silanol

most important reason for this is the absence of silica in the zirconia bonds

microstructure which negates the possibility of etching as a rough- The results achieved by this process are conflicting as the hard-

ening method essential for mechanical bonding, as well as nullify the ness of Zirconia is a deterrent to achieving the embedding of silica

use of silanes, forming surfaces hydroxyls and developing the chem- particles and leads to stripping of the same. The pressure application

ical bond. of alumina particles lead to surface flaws leading to crack propaga-

There are various approaches which have been worked on to tion and fracture.Studies have shown that the TBS doesn’t provide

achieve predictable Zr/Cement bond. These methods try and utilize any advantage over the regular usage of self-adhesive resin cements

ways to achieve this by various surface treatments of Zirconia. e.g. Cojec, Rocatec 3M.

Access this article online http://dental-practice.biz/emagazine/dentalpractice/#p=24

Dental Practice // January-February 2021 // Vol 17 No 4 25