Page 43 - J0JAPS_VOL14

P. 43

Syarfadila / JOJAPS – JOURNAL ONLINE JARINGAN PENGAJIAN SENI BINA

3.0 THE DESIGN OF PEPPER SORTING MACHINE

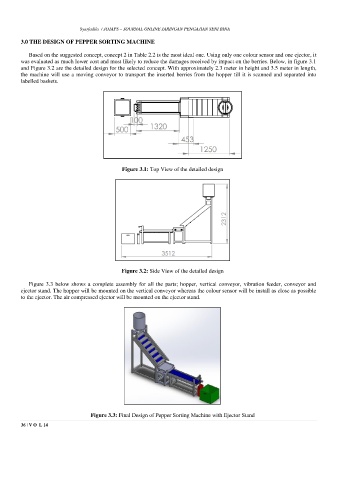

Based on the suggested concept, concept 2 in Table 2.2 is the most ideal one. Using only one colour sensor and one ejector, it

was evaluated as much lower cost and most likely to reduce the damages received by impact on the berries. Below, in figure 3.1

and Figure 3.2 are the detailed design for the selected concept. With approximately 2.3 meter in height and 3.5 meter in length,

the machine will use a moving conveyor to transport the inserted berries from the hopper till it is scanned and separated into

labelled baskets.

Figure 3.1: Top View of the detailed design

Figure 3.2: Side View of the detailed design

Figure 3.3 below shows a complete assembly for all the parts; hopper, vertical conveyor, vibration feeder, conveyor and

ejector stand. The hopper will be mounted on the vertical conveyor whereas the colour sensor will be install as close as possible

to the ejector. The air compressed ejector will be mounted on the ejector stand.

Figure 3.3: Final Design of Pepper Sorting Machine with Ejector Stand

36 | V O L 14