Page 190 - vol21_editedversion2

P. 190

Mohd Nurilhadi / JOJAPS – JOURNAL ONLINE JARINGAN PENGAJIAN SENI BINA 0197731035

3.35 7.0 14.0

1.18 36.3 72.6

0.850 10.5 21.0

0.500 10.0 20.0

0.365 5.1 10.2

0.106 5.3 10.6

3. Results and analysis

3.1. Mechanical testing

For mechanical testing, there are two testing that are conducted which is tensile test and impact

test(charrpy). The sample of ratio used is (epoxy: fiber)

Sample 1 (80:20)

Sample 2 (60:40)

Sample 3 (50:50)

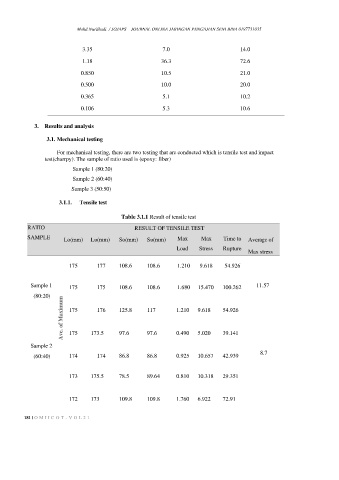

3.1.1. Tensile test

Table 3.1.1 Result of tensile test

RATIO RESULT OF TENSILE TEST

SAMPLE Lo(mm) Lu(mm) So(mm) Su(mm) Max Max Time to Average of

Load Stress Rupture

Max stress

175 177 108.6 108.6 1.210 9.618 54.926

Sample 1 175 175 108.6 108.6 1.680 15.470 100.262 11.57

(80:20)

Ave. of Maximum Stress

175 176 125.8 117 1.210 9.618 54.926

175 173.5 97.6 97.6 0.490 5.020 39.141

Sample 2

(60:40) 174 174 86.8 86.8 0.925 10.657 42.939 8.7

173 175.5 78.5 89.64 0.810 10.318 29.351

172 173 109.8 109.8 1.760 6.922 72.91

181 | O M I I C O T - V O L 2 1