Page 18 - PolyPak Pkg Management Price Book Apr 2022

P. 18

For more information and technical

assistance contact:

Poly Pak Packaging

2939 E. Washington Blvd

Los Angeles, CA 90023

323.264.2400

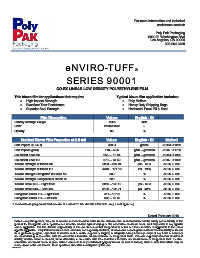

eNVIRO-TUFF®

SERIES 90001

CO-EX LINEAR LOW DENSITY POLYETHYLENE FILM

This blown film for applications that require: Typical blown film application includes:

High Impact Strength Poly Mailers

Excellent Tear Resistance Heavy Duty Shipping Bags

Superior Seal Strength Horizontal Form Fill & Seal

Film Discerption Values English - SI

Density Average Gauge .0025 inch

Color White/Silver --

Opacity 95 %

Nominal Blown Film Properties at 2.5 mil Values English - SI Method

Dart Impact (2.5 Mil) 296 G grams ASTM D 1209

Dart Impact (g/Mil) 118 – 4.65 g/mil – g/micron ASTM D 1709

Elmendorf Tear MD 255 --- 10.04 g/mil – g/micron ASTM D 1922

Elmendorf Tear TD 876 --- 34.49 g/mil – g/micron ASTM D 1922

Tensile Strength at Break MD 5264 – 207.24 psi - MPa ASTM D 882

Tensile Strength at Break TD 4346 -- 171.10 Psi - MPa ASTM D 882

Tensile strength Elongation at Break MD 563 % ASTM D 882

Tensile Strength Elongation at Break TD 728 % ASTM D 882

Tensile break MD….Right Seal 3256 – 128.19 psi - MPa ASTM D 882

Tensile Break MD….Left Seal 3193 – 125.71 psi - MPa ASTM D 882

Elongation Break TD….Right Seal 411—16.18 % ASTM F 882

Elongation Break TD….Left Seal 386 -- 15.20 % ASTM D 882

1. Produced using a grooved feed extruder at a rate of 18 lb/in die with a 2.5 BUR using a dual lip air ring

Dated February 2010

Before using this product, the user is advised and cautioned to make its own determination and assessment of the safety and suitability of the

product for the specific use in question and is further advised against relying on the information contained herein as it may relate to any specific

use or application. It is the ultimate responsibility of the user to ensure that the product is suited and the information is applicable to the user’s

specific application. Poly Pak America Inc does not make, and expressly disclaims, all warranties, including warranties of merchantability or fitness

for a particular purpose, regardless of whether oral or written express or implied, or allegedly arising from any usage of any trade or from any

course of dealing in connection with the use of the information contained herein or the product itself. The user expressly assumes all risk and

liability, whether based in contract, tort or otherwise, in connection with the use of the information contained herein or the product itself. Further,

information contained herein is given without reference to any intellectual property issues, as well as federal, state or local laws which may be

encountered in the use thereof. Such questions should be investigated by the user.

Rev 5/18/18