Page 3 - April 2021 Track N Times

P. 3

FEATURE STORY

Eye Care Safety

By Sam Madsen, Manager Rail Grinding

What: Prior to 2015 dust in eye injuries through the years was an injury common to rail grinding due

to the amount of dust transmitted from grinding. Initiatives and efforts were t taken to reduce dust in eye

injuries, but over time different items and processes were not effective.

So, What: The more grinding that we do the trends of dust in eye injuries continue to go in the wrong

direction. This is in not acceptable to Loram, our customers are also concerned on our safety trend going

the wrong way to the extent of negative feedback on how are you (LORAM) going to fix this problem.

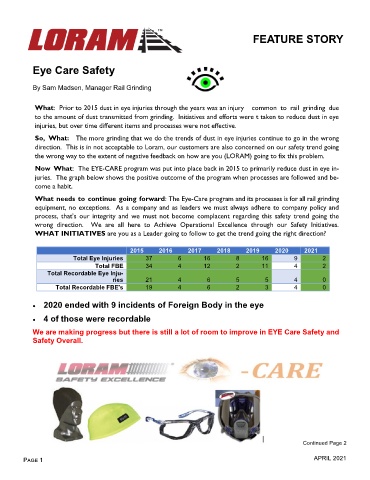

Now What: The EYE-CARE program was put into place back in 2015 to primarily reduce dust in eye in-

juries. The graph below shows the positive outcome of the program when processes are followed and be-

come a habit.

What needs to continue going forward: The Eye-Care program and its processes is for all rail grinding

equipment, no exceptions. As a company and as leaders we must always adhere to company policy and

process, that’s our integrity and we must not become complacent regarding this safety trend going the

wrong direction. We are all here to Achieve Operational Excellence through our Safety Initiatives.

WHAT INITIATIVES are you as a Leader going to follow to get the trend going the right direction?

2015 2016 2017 2018 2019 2020 2021

Total Eye Injuries 37 6 16 8 16 9 2

Total FBE 34 4 12 2 11 4 2

Total Recordable Eye Inju-

ries 21 4 6 5 5 4 0

Total Recordable FBE's 19 4 6 2 3 4 0

• 2020 ended with 9 incidents of Foreign Body in the eye

• 4 of those were recordable

We are making progress but there is still a lot of room to improve in EYE Care Safety and

Safety Overall.

Continued Page 2

APRIL 2021

Page 1