Page 20 - Graypvine August 2021

P. 20

PROJECT SPOTLIGHT

20 Team Keurig works

with unique long-term

schedule

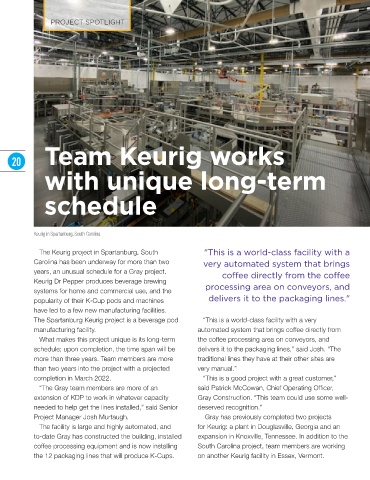

Keurig in Spartanburg, South Carolina

The Keurig project in Spartanburg, South "This is a world-class facility with a

Carolina has been underway for more than two very automated system that brings

years, an unusual schedule for a Gray project. coffee directly from the coffee

Keurig Dr Pepper produces beverage brewing processing area on conveyors, and

systems for home and commercial use, and the

popularity of their K-Cup pods and machines delivers it to the packaging lines."

have led to a few new manufacturing facilities.

The Spartanburg Keurig project is a beverage pod “This is a world-class facility with a very

manufacturing facility. automated system that brings coffee directly from

What makes this project unique is its long-term the coffee processing area on conveyors, and

schedule; upon completion, the time span will be delivers it to the packaging lines,” said Josh. “The

more than three years. Team members are more traditional lines they have at their other sites are

than two years into the project with a projected very manual.”

completion in March 2022. “This is a good project with a great customer,”

“The Gray team members are more of an said Patrick McCowan, Chief Operating Officer,

extension of KDP to work in whatever capacity Gray Construction. “This team could use some well-

needed to help get the lines installed,” said Senior deserved recognition.”

Project Manager Josh Murtaugh. Gray has previously completed two projects

The facility is large and highly automated, and for Keurig: a plant in Douglasville, Georgia and an

to-date Gray has constructed the building, installed expansion in Knoxville, Tennessee. In addition to the

coffee processing equipment and is now installing South Carolina project, team members are working

the 12 packaging lines that will produce K-Cups. on another Keurig facility in Essex, Vermont.