Page 22 - ILPT catalogue

P. 22

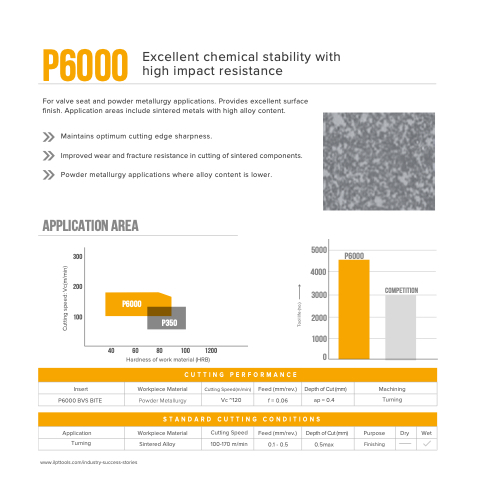

P6000

For valve seat and powder metallurgy applications. Provides excellent surface finish. Application areas include sintered metals with high alloy content.

Maintains optimum cutting edge sharpness.

Improved wear and fracture resistance in cutting of sintered components. Powder metallurgy applications where alloy content is lower.

Excellent chemical stability with high impact resistance

application area

300 200

100

5000 P6000 4000

3000

2000

1000 0

competition

40

p6000

60

p350

80 100

1200

Hardness of work material (HRB)

CUTTING PERFORMANCE

Insert

Workpiece Material

Cutting Speed(m/min)

Feed (mm/rev.)

Depth of Cut (mm)

Machining

P6000 BVS BITE

Powder Metallurgy

Vc ~120

f = 0.06

ap = 0.4

Turning

STANDARD CUTTING CONDITIONS

Application Workpiece Material Cutting Speed Feed (mm/rev.) Depth of Cut (mm) Purpose Dry Wet

Turning Sintered Alloy 100-170 m/min

0.1 - 0.5 0.5max Finishing

www.ilpttools.com/industry-success-stories

Cutting speed: Vc(m/min)

Tool life (no.)