Page 44 - ILPT catalogue

P. 44

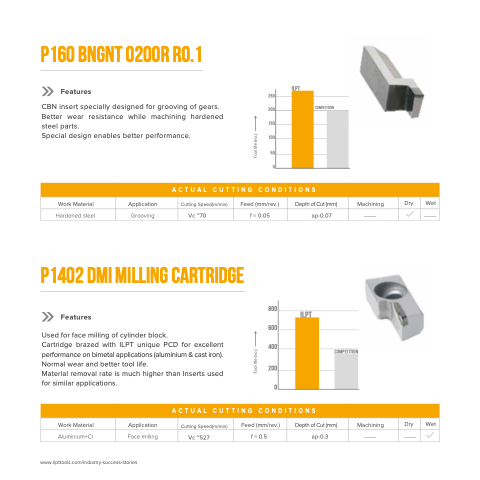

P160 Bngnt 0200r r0.1

Features

ILPT 250

CBN insert specially designed for grooving of gears. 200

Better wear resistance while machining hardened

steel parts.

Special design enables better performance. 100

competition

P1402 DMi milling cartridge

Features

Used for face milling of cylinder block.

Cartridge brazed with ILPT unique PCD for excellent performance on bimetal applications (aluminium & cast iron). Normal wear and better tool life.

Material removal rate is much higher than Inserts used for similar applications.

800 600 400

200 0

ILPT

competition

150

50 0

ACTUAL CUTTING CONDITIONS

Work Material

Application

Cutting Speed(m/min)

Feed (mm/rev.)

Depth of Cut (mm)

Machining Dry Wet

Hardened steel

Grooving

Vc ~70

f = 0.05

ap-0.07

ACTUAL CUTTING CONDITIONS

Work Material

Application

Cutting Speed(m/min)

Feed (mm/rev.)

Depth of Cut (mm)

Machining Dry Wet

Aluminium+CI

Face milling

Vc ~527

f = 0.5

ap-0.3

www.ilpttools.com/industry-success-stories

Tool life (no.) Tool life (no.)