Page 48 - ILPT catalogue

P. 48

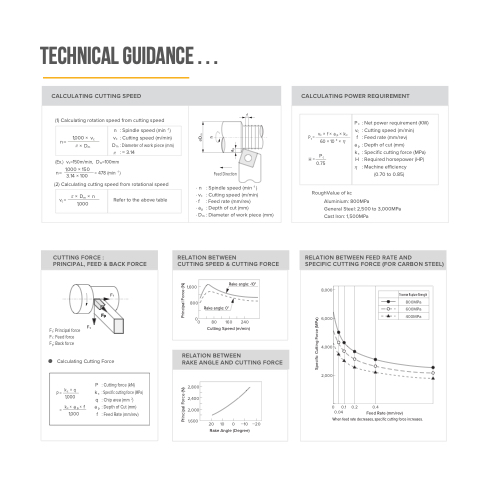

TECHNICAL GUIDANCE . . .

CALCULATING CUTTING SPEED

(1) Calculating rotation speed from cutting speed

(Ex.) vc=150m/min, Dm=100mm

n = 1,000 × 150 = 478 (min -1 ) 3.14 × 100

(2) Calculating cutting speed from rotational speed

n = 1,000 × vc × Dm

n : Spindle speed (min -1 ) vc : Cutting speed (m/min) Dm : Diameter of work piece (mm)

: ≈ 3.14

vc=

× Dm × n 1,000

Refer to the above table

f

· n : Spindle speed (min -1 ) · vc : Cutting speed (m/min) · f : Feed rate (mm/rev)

· ap : Depth of cut (mm)

· Dm : Diameter of work piece (mm)

Feed Direction

CALCULATING POWER REQUIREMENT

Pc= vc×f×ap×kc 60 × 10 3 ×

H= Pc 0.75

Pc : Net power requirement (KW) vc : Cutting speed (m/min)

f : Feed rate (mm/rev)

ap : Depth of cut (mm)

kc : Specific cutting force (MPa)

H : Required horsepower (HP) : Machine efficiency

(0.70 to 0.85)

RoughValue of kc Aluminium: 800MPa

General Steel: 2,500 to 3,000MPa Cast Iron: 1,500MPa

CUTTING FORCE :

PRINCIPAL, FEED & BACK FORCE

Ff Fp

● Calculating Cutting Force

Fc: Principal force Fc Ff : Feed force

Fp: Back force

P= kc ×q 1,000

kc × a p × f 1,000

P k c q a p f

: Cutting force (kN)

: Specific cutting force (MPa) : Chip area (mm 2)

: Depth of Cut (mm)

: Feed Rate (mm/rev)

=

RELATION BETWEEN FEED RATE AND

SPECIFIC CUTTING FORCE (FOR CARBON STEEL)

8,000

6,000

4,000

2,000

0 0.1 0.2 0.4

Traverse Rupture Strength

800MPa

600MPa

400MPa

0.04

Feed Rate (mm/rev)

When feed rate decreases, specific cutting force increases.

RELATION BETWEEN

CUTTING SPEED & CUTTING FORCE

Rake angle: -10°

Rake angle: 0°

1,600 800

00 80 160 240

Cutting Speed (m/min)

RELATION BETWEEN

RAKE ANGLE AND CUTTING FORCE

2,800

2,400

2,000

1,600

20 10 0 -10 -20 Rake Angle (Degree)

Principal Force (N) Principal Force (N)

Specific Cutting Force (MPa)

ap

øDm n