Page 49 - ILPT catalogue

P. 49

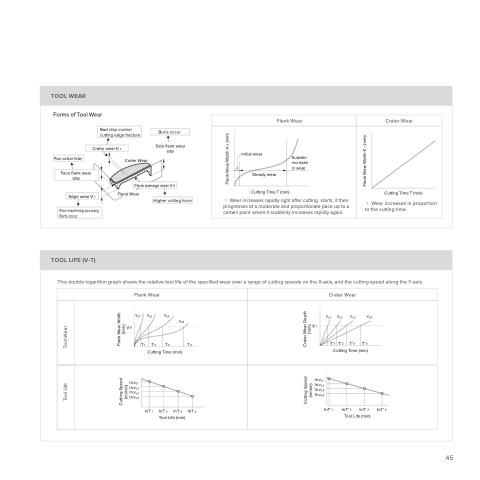

TOOL WEAR

Forms of Tool Wear

Flank Wear

Crater Wear

Initial wear

Sudden increase in wear

・ Wear increases rapidly right after cutting starts, it then progresses at a moderate and proportionate pace up to a certain point where it suddenly increases rapidly again.

Steady wear

Cutting Time T (min)

Cutting Time T (min)

・ Wear increases in proportion to the cutting time.

Bad chip control cutting edge fracture

Burrs occur

Poor surface finish

Crater wear K T

Crater Wear

Face flank wear VN2

Side flank wear VN1

Edge wear V C

Flank average wear V B Flank Wear

Higher cutting force

Poor machining accuracy, Burrs occur

TOOL LIFE (V-T)

This double logarithm graph shows the relative tool life of the specified wear over a range of cutting speeds on the X-axis, and the cutting speed along the Y-axis.

Flank Wear

Crater Wear

vc1 vc2 vc3

vc4

VB

T1T2T3 T4 Cutting Time (min)

vc1 vc2 vc3 vc4 KT

T'1 T'2 T'3 T'4 Cutting Time (min)

In vc1 In vc2 In vc3 In vc4

InT1 InT2 InT3 InT4 Tool Life (min)

In vc1 In vc2 In vc3 In vc4

InT' 1

InT' 2 InT' 3 InT' 4 Tool Life (min)

45

Tool Life

Tool Wear

Cutting Speed (m/min)

Flank Wear Width (mm)

Cutting Speed (m/min)

Crater Wear Depth (mm)

Flank Wear Width V B (mm)

Flank Wear Width K T (mm)