Page 30 - The Complete Rigger’s Apprentice

P. 30

come into contact with them; on mooring lines where

they pass through chocks; and on grommets that go

around rope-stropped blocks. When sealed with tar,

service prevents rot and corrosion in the steel rigging

it covers. Made over Spectra, it protects that material

from ultraviolet as well as chafe. Served Spectra is

basically immortal.

Service

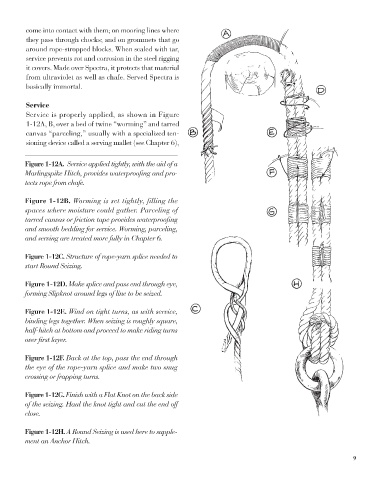

Service is properly applied, as shown in Figure

1-12A, B, over a bed of twine “worming” and tarred

canvas “parceling,” usually with a specialized ten-

sioning device called a serving mallet (see Chapter 6),

Figure 1-12A. Service applied tightly, with the aid of a

Marlingspike Hitch, provides waterproofing and pro-

tects rope from chafe.

Figure 1-12B. Worming is set tightly, filling the

spaces where moisture could gather. Parceling of

tarred canvas or friction tape provides waterproofing

and smooth bedding for service. Worming, parceling,

and serving are treated more fully in Chapter 6.

Figure 1-12C. Structure of rope-yarn splice needed to

start Round Seizing.

Figure 1-12D. Make splice and pass end through eye,

forming Slipknot around legs of line to be seized.

Figure 1-12E. Wind on tight turns, as with service,

binding legs together. When seizing is roughly square,

half-hitch at bottom and proceed to make riding turns

over first layer.

Figure 1-12F. Back at the top, pass the end through

the eye of the rope-yarn splice and make two snug

crossing or frapping turns.

Figure 1-12G. Finish with a Flat Knot on the back side

of the seizing. Haul the knot tight and cut the end off

close.

Figure 1-12H. A Round Seizing is used here to supple-

ment an Anchor Hitch.

9