Page 122 - Modernfold Architectural Products

P. 122

Acousti-Seal 932 Technical Data

®

10 22 26 (10650) Operable Partitions

ACOUSTI-SEAL 900 SERIES TECHNICAL DATA

®

a. Pass door to be prime painted for field C. Match operable partitions by installing panels

finishing. from marked packages in numbered sequence

b. Pass door to be painted one consistent indicated on Shop Drawings.

color from manufacturer’s standard D. Broken, cracked, chipped, deformed, or

offering. unmatched panels are not acceptable.

2. Matching pass door same thickness and

appearance as panels. ADA-compliant pass 3.2 CLEANING AND PROTECTION

door to be trimless and equipped with friction A. Clean partition surfaces upon completing

latch and flush pulls for panic operation. No installation of operable partitions to remove

threshold will be permitted. dust, dirt, adhesives, and other foreign materials

3. Hardware according to manufacturer’s written instructions.

a. Automatic door closures. B. Provide final protection and maintain conditions

b. Self-Illuminated exit signs. in a manner acceptable to the manufacturer

c. Panic hardware. and Installer that insure operable partitions are

B. Work Surfaces: without damage or deterioration at time of

1. Markerboard: White enamel on steel, bonded Substantial Completion.

to the face of the panel with horizontal

trim without exposed fasteners. Trim is not 3.3 ADJUSTING

acceptable on vertical edges to provide A. Adjust operable partitions to operate smoothly,

uninterrupted work surface. easily, and quietly, free from binding, warp,

2. Tackboard: Minimum 1/4-inch (6.35 mm) excessive deflection, distortion, nonalignment,

natural cork, covered with vinyl or fabric, with misplacement, disruption, or malfunction,

horizontal trim without exposed fasteners. Trim throughout entire operational range. Lubricate

is not acceptable on vertical edges. hardware and other moving parts.

C. Available Accessories/Options:

1. Pocket Doors: Acousti-Seal Pocket Doors by 3.4 EXAMINATION

®

Modernfold, Inc., with same construction, finish, A. Examine flooring, structural support, and opening,

and appearance as the adjacent panels. with Installer present, for compliance with

2. Finished end caps. requirements for installation tolerances and other

3. Intersecting partition interface. conditions affecting performance of operable

4. Inset window options - glazed or unglazed. partitions. Proceed with installation only after

unsatisfactory conditions have been corrected.

PART 3 – EXECUTION

3.5 DEMONSTRATION

3.1 INSTALLATION A. Demonstrate proper operation and maintenance

A. General: Comply with ASTM E557, operable procedures to Owner’s representative.

partition manufacturer’s written installation B. Provide Operation and Maintenance Manual to

instructions, Drawings and approved Shop Owner’s representative.

Drawings.

B. Install operable partitions and accessories after

other finishing operations, including painting

have been completed.

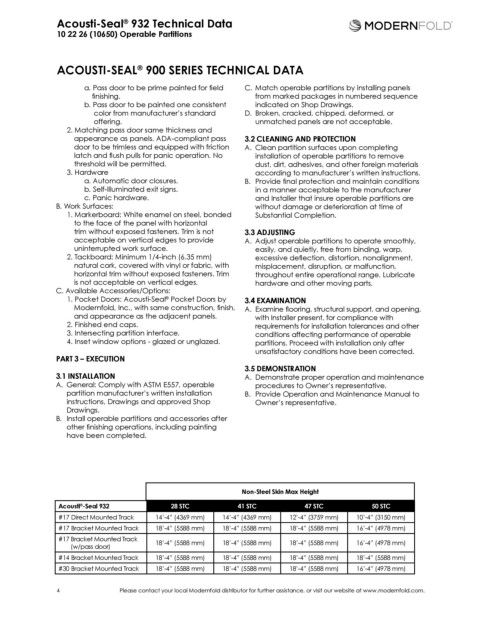

Non-Steel Skin Max Height

Acousti -Seal 932 28 STC 41 STC 47 STC 50 STC

®

#17 Direct Mounted Track 14’-4” (4369 mm) 14’-4” (4369 mm) 12’-4” (3759 mm) 10’-4” (3150 mm)

#17 Bracket Mounted Track 18’-4” (5588 mm) 18’-4” (5588 mm) 18’-4” (5588 mm) 16’-4” (4978 mm)

#17 Bracket Mounted Track 18’-4” (5588 mm) 18’-4” (5588 mm) 18’-4” (5588 mm) 16’-4” (4978 mm)

(w/pass door)

#14 Bracket Mounted Track 18’-4” (5588 mm) 18’-4” (5588 mm) 18’-4” (5588 mm) 18’-4” (5588 mm)

#30 Bracket Mounted Track 18’-4” (5588 mm) 18’-4” (5588 mm) 18’-4” (5588 mm) 16’-4” (4978 mm)

4 Please contact your local Modernfold distributor for further assistance, or visit our website at www.modernfold.com.