Page 26 - 20200511

P. 26

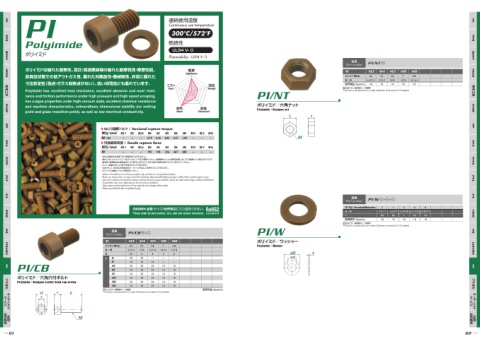

PI ࿈ଓ༻Թ PC

PC

Continuous use temperature

300°C/572°F

Polyimide ೩মੑ PPS

PPS

6- 7

ϙϦΠϛυ RENY

Flammability : UL94 V- 0

RENY

൪ M

Part number PI/NT ˓

ϙϦΠϛυ༏Εͨੑɺߴѹɾߴࡲա࣌ͷ༏Εͨຎੑɾຎࡲੑೳɺ ܰྔ M M3 M4 M5 M6 M8

Lightness PEEK

ߴਅۭঢ়ଶͰͷΞτΨεੑɺ༏Εͨରༀੑɾػցಛੑɺඇৗʹ༏Εͨ ϐον/ Pitch 0.5 0.7 0.8 1 1.25

PEEK

B ʷ H 5.5ʷ2.4 7ʷ3.2 8ʷ4 10ʷ5 13ʷ6.5

ੇ๏҆ఆੑʢ༥ɾΨϥεసҠ͕ͳ͍ʣɺ͍ಋిੑʹ༏Ε͍ͯ·͢ɻ ൢച୯Ґ Quantity 10 10 10 10 10

ίετ ڧ

डͰ͢ɻʢೲظ ʙ िؒʣ

Polyimide has excellent heat resistance, excellent abrasion and wear resis- Cost Strength 5IJT QBSU JT QSPEVDUJPO PO PSEFS %FMJWFSZ UJNF BCPVU XFFLT ઐ༻۩

tance and friction performance under high pressure and high speed scraping, PI/NT

ઐ༻۩

low outgas properties under high vacuum state, excellent chemical resistance

ϙϦΠϛυʗ֯φοτ

and machine characteristics, extraordinary dimensional stability (no melting

ༀ Polyimide / Hexagon nut PVDF

point and glass transition point), as well as low electrical conductivity. Heat Chemical

PVDF

# )

PP

⾣Ͷ͡ΓഁஅτϧΫ Torsional rupture torque PP

M1.7 M2 M2.6 M3 M4 M5 M6 M8 M10 M12 M16

୯Ґ Unit

– – – 0.19 0.32 0.42 0.51 1.09 – – – M

Nɾm

⾣Ҿுഁஅՙॏ Tensile rupture force PFA

M1.7 M2 M2.6 M3 M4 M5 M6 M8 M10 M12 M16

PFA

୯Ґ Unit

– – – 193 445 526 607 805 – – –

N

ɾ දதͷࢀߟͰ͋ΓอূͰ͋Γ·ͤΜɻ

ɾ కʹτϧΫυϥΠόʔٴͼτϧΫϨϯνΛ͝༻͍ͩ͘͞ɻਪకτϧΫ༻ঢ়ଶʹ͓͍ͯͷഁஅτϧΫͷ ˋͰ͢ɻ PTFE

ɾ ੑɺༀੑ༻݅ʹΑΓมԽ͠·͢ͷͰɺඞͣࣄલʹ༻ঢ়ଶͰͷςετΛߦ͍ͬͯͩ͘͞ɻ

ɾ ϩοτɺ֤छ݅ʹΑΓएׯม৭͢Δ͜ͱ͕͋Γ·͢ɻ

PTFE

ɾ ࡏݿαΠζɺܗঢ়ٴͼ༻ࡐྉϝʔΧʔ༧ࠂͳ͘มߋ͢Δ͜ͱ͕͋Γ·͢ɻ

ɾ ϙϦΠϛυઈס͔ͯ͠Βޚ༻͍ͩ͘͞ɻ

ɾ Values in the table are for reference purpose only, and they are not guaranteed values.

ɾ Please use torque driver or torque wrench for fastening. Recommended fastening torque is 50% of the torsional rupture torque. PVC

ɾ Since heat resistance and chemical resistance change based on usage conditions, please test under actual usage conditions beforehand.

PVC

ɾ Discoloration may occur depending on lot and various conditions.

ɾ Sizes, shapes and manufacturers of raw materials may change without notice.

ɾ Please use polyimide after completely drying.

൪ d D t PA

PA

Part number PI/W ˓-˓-˓

ݺͼܘ/ Nominaldiameter 3 4 5 6 8

ORDER⾣൪ɾαΠζɾൢച୯Ґʹͯ͝จ͍ͩ͘͞ɻ d ʷ D 3.2ʷ7 4.3ʷ9 5.3ʷ10 6.4ʷ12.5 8.4ʷ17

Please order by part number, size, and unit volume increment. POM

t 0.5 0.8 1 1.6 1.6

POM

ൢച୯Ґ Quantity 10 10 10 10 10

डͰ͢ɻʢೲظ ʙ िؒʣ

5IJT QBSU JT QSPEVDUJPO PO PSEFS %FMJWFSZ UJNF BCPVU XFFLT

൪ M L PI/W PS

Part number PI/CB ˓-˓

PS

M M3 M4 M5 M6 M8 ϙϦΠϛυʗϫογϟʔ

ϐον/ Pitch 0.5 0.7 0.8 1 1.25 Polyimide / Washer

D ʷ H 5.5ʷ3 7ʷ4 8.5ʷ5 10ʷ6 13ʷ8 CERAMIC

B 2.5 3 4 5 6 ПD t

CERAMIC

L 6 10 10 — — — Пd

8 10 10 10 — —

PI/CB 10 10 10 10 10 10 PI

PI

12

10

10

10

10

10

16 10 10 10 10 10

ϙϦΠϛυʗ֯݀Ϙϧτ 20 10 10 10 10 10

Polyimide / Hexagon socket head cap screw 30 10 10 10 10 10 ϓϥͶ

40 10 10 10 10 10

डͰ͢ɻʢೲظ ʙ िؒʣ ൢച୯Ґ Quantity

ϓϥͶ

П% ) L 5IJT QBSU JT QSPEVDUJPO PO PSEFS %FMJWFSZ UJNF BCPVU XFFLT

# αʔϏε ΦʔμʔϝΠ υ

αʔϏε

ΦʔμʔϝΠ υ

M ٕज़ࢿྉ ࡐ࣭

ࡐ࣭

ɾ

ɾ

ٕज़ࢿྉ

⾣⾣⾣61 62 ⾣⾣⾣