Page 2 - Davidson News - 2019 Q4

P. 2

CI/ECO News: 2019 Quarter 4

Happy New Year from your friends at Davidson Plyforms! We hope you had a great holiday

season and are just as eager as us to tackle the new year 2020. In this issue of the Davidson Digest

you will read about new and exciting projects that have rounded out our 2019 and carried into 2020.

We also are continuing to tackle projects on the ECO front that make sense for sustainability in

reducing our environmental footprint. We hope you enjoy this small glimpse into Davidson Plyforms!

CI: BACCI Installation

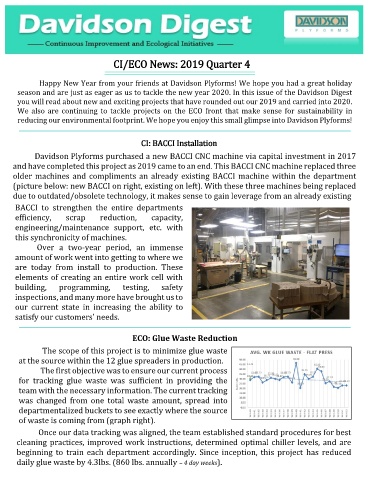

Davidson Plyforms purchased a new BACCI CNC machine via capital investment in 2017

and have completed this project as 2019 came to an end. This BACCI CNC machine replaced three

older machines and compliments an already existing BACCI machine within the department

(picture below: new BACCI on right, existing on left). With these three machines being replaced

due to outdated/obsolete technology, it makes sense to gain leverage from an already existing

BACCI to strengthen the entire departments

efficiency, scrap reduction, capacity,

engineering/maintenance support, etc. with

this synchronicity of machines.

Over a two-year period, an immense

amount of work went into getting to where we

are today from install to production. These

elements of creating an entire work cell with

building, programming, testing, safety

inspections, and many more have brought us to

our current state in increasing the ability to

satisfy our customers’ needs.

ECO: Glue Waste Reduction

The scope of this project is to minimize glue waste

at the source within the 12 glue spreaders in production.

The first objective was to ensure our current process

for tracking glue waste was sufficient in providing the

team with the necessary information. The current tracking

was changed from one total waste amount, spread into

departmentalized buckets to see exactly where the source

of waste is coming from (graph right).

Once our data tracking was aligned, the team established standard procedures for best

cleaning practices, improved work instructions, determined optimal chiller levels, and are

beginning to train each department accordingly. Since inception, this project has reduced

daily glue waste by 4.3lbs. (860 lbs. annually – 4 day weeks).