Page 36 - Sustainability report 2018 Ratti Group

P. 36

CHAPTER 3 | Material becomes creation

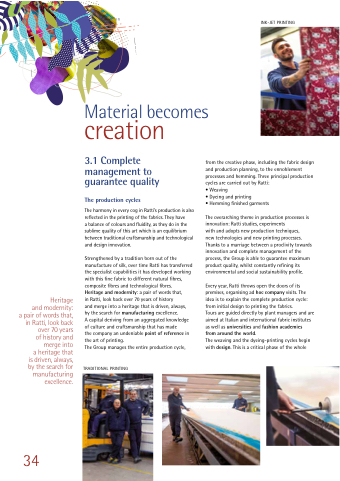

INK-JET PRINTING

Heritage and modernity: a pair of words that, in Ratti, look back over 70 years of history and merge into a heritage that is driven, always, by the search for manufacturing excellence.

creation

3.1 Complete management to guarantee quality

The production cycles

The harmony in every cog in Ratti’s production is also reflected in the printing of the fabrics. They have

a balance of colours and fluidity, as they do in the sublime quality of this art which is an equilibrium between traditional craftsmanship and technological and design innovation.

Strengthened by a tradition born out of the manufacture of silk, over time Ratti has transferred the specialist capabilities it has developed working with this fine fabric to different natural fibres, composite fibres and technological fibres.

Heritage and modernity: a pair of words that,

in Ratti, look back over 70 years of history

and merge into a heritage that is driven, always, by the search for manufacturing excellence.

A capital deriving from an aggregated knowledge of culture and craftsmanship that has made

the company an undeniable point of reference in the art of printing.

The Group manages the entire production cycle,

TRADITIONAL PRINTING

from the creative phase, including the fabric design and production planning, to the ennoblement processes and hemming. Three principal production cycles are carried out by Ratti:

• Weaving

• Dyeing and printing

• Hemming finished garments

The overarching theme in production processes is innovation: Ratti studies, experiments

with and adopts new production techniques,

new technologies and new printing processes. Thanks to a marriage between a proclivity towards innovation and complete management of the process, the Group is able to guarantee maximum product quality, whilst constantly refining its environmental and social sustainability profile.

Every year, Ratti throws open the doors of its premises, organising ad hoc company visits. The idea is to explain the complete production cycle: from initial design to printing the fabrics.

Tours are guided directly by plant managers and are aimed at Italian and international fabric institutes as well as universities and fashion academies from around the world.

The weaving and the dyeing-printing cycles begin with design. This is a critical phase of the whole

34

Material becomes