Page 32 - Toyota Annual Directory 2020-2021

P. 32

AGC) 8 %

5,93 min (

PROCESS DESCRIPTION

N

IMPACT

UNIT

ROBOT AREA

checking operations W gripper TA

TBIRT) IVENESS

hecking first parts

u c t i o n ( A G C ) duction (TBR)

er m CGM TA hours worked)

6.Yokoten to other

u

evious mold 3IP0TIO%N aenxgtemovldertime

M

CONDITION TARGET

9,5

min 15,53 9,5 9,6 -5,93

o

T

S

t

u

d

y

sp

illion

ctionP R(DOIC

tion (KNAUF)

ecking and lubricating

PEOS

S) D E

6.Yokoten to

Injection shop

reduction

E Background: Overt 1

UCTION

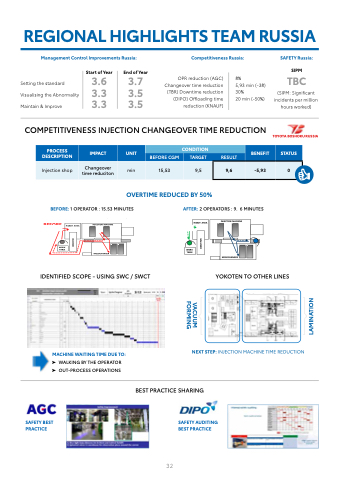

reduced by 50%

o / CT Study

T

BENEFIT STATUS

SCR

9 o

REGIONAL HIGHLIGHTS TEAM RUSSIA

# eemaernt Control ImprovemeAnGtsCRInUte:rnal Use OnlyC.

ompetitiveness RUSI:PM (DIPO) OSafflfeotaydRinUg: time 20 min (-50%) collection

Maintain & Improve

ng the standard 3.6 M RUSSIA

O u t - p r o3c0e %s s ( S I P M : S i g i n i f i c a n t Downtime reduction (DIPO)

I N J E C

30 %

SWCT

NGER

W C / SW CT

est

e

Safety best

practice

illdN P

SAFETY BEST PRACTICE

6.Yokoten to other lines

8 I %N J E C T INJECT 5,93 min (-3

p l a c e m 3 e . n 5 t O v e r t i m e r e d u

OITMAPABCOT SHOKUORfUflSoSa ction (KNA STATUS

MOLDCHANGER

Safety best practice

WORK TABLE

Auditing

Start of Year End of Year

8 % Maintain & improve 3.3 3.5 SIPM Preparing m olds for replacem ent

OPRreduction(AGC) Changeover time reduction (TBR)

5,93 min (-38%) collection OPR reduction (AGC) 8 %

Offloadingtimereduction(KNAUoF)peratio2n0smin(-50%) incidentspermillion Parallel

Downtime reduction (DIPO)

he abnormality 3.3

Offloading time reduction (KNAUF)

30 % (SIPM: Siginificant 20 mDoiwnn(3t-i5m.0eS%rei)mducutioilnac(iDtdIePnOdt)s pNeremwillioPnrocess

20 min (-50%) incidents per million Parallel

R

SIPM

operations

setup

setup

3.7

Ch3a0ng%eover time reductio(nSI(PTMBR:)Siginif5ic,9a3ntmin (-38%)

collection

Preparing m olds for replacem ent

Loading the next mold

Unloading the previous mold

setup

3.5

tain & improve 3.3

s RU: COMPESTaIfeTtIyVRUE:NESOffSloadIiNng tJimEe rCedTuctIioOn (KNhAoUuCFr)s HworAkeNd) GEOVER TIME REDUCTION

Before: 1 op

.53 min

es

After : 2 opAepraptloircsa:t9io.6nmoinfutthees approach to similar processes

MACHINE WAITING TIME DUE TO:

- walking by the operator ➤ WALKING BY TH- oEutO-pProEceRssAoTpOerRations

Next step:

Injection MachineTime reductionSafety

Next step:

➤ O4UT-PiRlOl CdESNS OPPERATIONS Best Practice Sharing

Injection Machine Time reduct

e

r

P

t

UNIT

CONDITION

BEFORE CGM TARGET RESULT

Next step:

RO

C

a

ES

t

o

r

:

1

5

u

S

DE

SC

RIP

TIO

N

IM

MOLDCHANGER Injection

PAC

AGC Internal Use Only.#

AGC Internal Use Only.

Management Control Improvements Russia: Competitiveness Russia: SAFETY Russia:

#

3

GHTS - TEAM RUSSIA

Visualising the Abnormality

Start of Year End of Year

AGC Internal Use Only.

#

SIPM

REGIONAL HIGHLIGHTS - TEAM RUSSIA

3.6 3.7

3. Simulated New ProcesTsBC Changeover time reduction 5,93 min (-38)

REGIONAL HIGHLIGHTS - TEAM RUSSIA

Competitiveness RU: Safety RStaUrt:of Year End of Year SIPM

Setting the standard

Management Control Improvements RU: Competitiveness RU: Safety RU:

3.3 3.5

IPO)

OA U VF ) E R 2T0 I mMi n ( - E5 N 👍

GEOVER TIME REDU

N

Injectionshop

g r i p p e r

SULT

hecking first parts

o

OGO> OGO> <LOG

BEFORE

RESULT

IDENTIFIEDSCOPvEe-rUtSimINGeSrWedCu/cSeWdCTby 50% Y6O.YKoOkoTtEeNntToOoOthTeHrlEinResLINES

TOYOTA BO2S.HIOdKeUntRiUfiSeSdIAScopPReOC-EUSSsDinESgCRSIPWTIOCN / SWCT IMPACT

O

vert

i

m

e reduced by 50%

ROBOT AREA INJECTION MAOCHLIDNECHANGER

CONDITION

UNIT BENEFIT STATUS

Injection shop Cnangeover time reduction

E

SULT

2. Identified Scope - Using SWC / SWCT

9,6

5. Results

Inje

15

ct

ion

sh

OPR reduction (AGC) 8%

O u t - p r o c e s s 3 . S i m 8u %l a t e d N e w D aPt a r uon dc e er s s Setting the standard 3.6 3.7 OPR reductionC(AhGaC)ngeover Time-9.6 min

(TBR) Downtime reduction 30% (SIPM: Significant

op

Parallel

CheckingLaoandinlgubthreicnaetxitnmg old 4. Trialled New Process

Aao

Manage o d PR

6.Yokoten to other lines

ET BEFORE CGM TARG

R

Cn

er tim

W

PKRO

M T A R G E T< L O G O >

re 9,5 9,6 -5,93

angeov

e

ed

by 50%

C

OR T A B L E

C

BENEFIT STATUS

Application of the approach to similar processes

T

Data under

Unloading the previous mold hours worked) work

I

O

v

u

c

e

d

ced

bCOyN

O

SSIA

<LOG

O

ESS

DESCRIPTION

RE

m

operations

5,93 mini(n-3c8i%d)ents per million

Visualising the abnormality 3.3 3.5

3.3 3.5Dataunder reduction(KNAUF) ChoanugresowvoerkTeidm)e-9.6min

Changeover time reduction (TBR)

3.5 COMPETITIVENESS Checking and lubricating

Changeover Time-9.6 min

work Calibration

O u t - p r o c e s s I N J E C T I O N C H A N G E O V E R T I M E R E D wU o C r k T I O N A F T E

R

hours worked)

TO

YOTA BOSHOKU RUSSIA

S

in

reduction a rts

TABLE Downtime redRuOBcOtiToAnRE(ADI (SIPM: Siginificant

checkCiOnNgDoITpIOeNrationsINJECTION MACHINE

min 15,53

Calibration Application of the approach to similar processes okoten to other lines

P E T 2 I T . I I V d E e N n E S t S i f i e d S c o p e - U s i n g S W C 5 / . S R We s C u T l t s

Cnang

nc

ident

Calibration

CESS DESCRIPTION Setti REGIONHM

0

UNIT Visualising B

BEFORE S

4. Tria

lled New Process

jection shop Main

Management Control Improvements RU:

OffCloaodimng tpime treidtuicvtioenn(KeNAsUsF)RU:20 min (-50%)

S

fetyPaRraUlle:l

5. Results

reduction

min 15,53 AGC Intern9al,U5se Only.

a

INJECTION MACHINE O

checking operaotiopnserations ckground: Overtime reduction by 5R0%EGIONAL HIGHLIGHTS - TEAM RU

SIA

AFTER

ua

lisi

US

SIA

Unloading the previous mold

Cnangeovertime

5

0

%

S

3.6 3.7 OPRreduction(AGC) MOLDCHANGER

BEFORECGM

TEA

A

ng

the abnormality

min reduction BEFORE CGM

COND1IT5IO,5N3

TARGET R

Main

tain &

imp

rove

3

M

R

ocess - Vide

o

/

3

T

S

t

u

3 d

S y

U

S

I

IN

JEC

TIO

N

C

HAN

GE

ReoTv

O(

ONDITION

TARGET RESULInTjection shop reduction

veness R

ound: OSvearfteimtye rRedUu:ction by 50% setup Data under

9,5

9,6

OPR

e

A F TER reduction

B

EFO

20 min (-50

E

s

U:

e

min 15,53 9,5

P

ROC

ESS D

ES

Ba

ckgr

ductiIonnj

8 c ( A t i Go n C ) c s h e h c o k i p n C g O N o D

Start of Year End of Year SIPM

R

B

Cnangeover time

15.53MINUTES AFTER:2OPERATORS:9C.na6ngMeoINveUrtiTmEeS

INJECTION MACHINE Overtime reduced by 50%

3

5

C

R

IP

.

TION IMP

EFO

RE

A

C

T

U N IT

Checking and lubricating

:1

OP

R:

COh

aVnEg

IeMr

tiEm

ReEreD

dUuc

CtiToIn

TNBR

5T

O(-S3H8O%

)

AinB

K )U R

, O9 Y3 O mT

min (-50%) incidents per million

Offloading time reduction (KNAUF) Parallel

ER

AT

O

1

5,5

3

9

,5

Ca

lib

BEFORE CGM TARGET RE

0

2

SU

LT

incidents per mill

n

9,6 setucphecking first parts

Calibration

Changeover Time-9.6 min

io

hourswRorkeepd)lacingthegrRipOpBeOrT AREA work

Out-process TABLE

5

.

R

esults

#

Downtime reductionCO(NDITPION) 30 % (SIPM: Siginificant Loading the next moldInjectionshop

MOLDCHANGER INJECTION MACHINE CO

y Settingthestandard

ON TOYOTA BOSHOKU RUSSIA OVERTIMEcolRlecEtioDn UCED BY 50%

R

OBOT

AREA

ORK Data under Replacing the gripper TABLE

o

checking first parts PROCESSDESCRIPTION 1. St COMPETITIVENESS 8 % Preparing molds for replacement

IMPACT

UNIT

u

d

i

e

d

P

r

o

c

e

s

s

-

V

i

d

e

/

C

T

S

t

u

dy

3.3 3.5 Management Control Improvements RU: Competitiveness RU: Safety RU:

C

ROBOT AREA Setting the standard 3.6 3.7 WORK

.

9 , 6f eY ewa r P r oE ncdeoshf soYu er s awro r k e d ) 4 . T r i a l l e d N e w P r o c e min work 5. Results

.

imu

l

atSteadrt oN

ration SIPM s

1. Studied Process - Video / CT StudCyhangeover Time-9.6 min

S I P M O u t - p r o c e s s 3 . 5 W O R CKh a o

5. R

e

s

u

lts

%r a t i o n s B E N E F I T S T A T U S BEFORE CGM TARGET RESULT

PROCESS DESCRIPTION

r

ITpIOeN

n

Rep5l,a9ci3ngmthiengr(i-p3pe8r%) collection

,53 9,5 9,6 -5,93 TABLE

g

e

o

ver time reductio

n

(TBR

)

IMPA

C

T

U

PROCESS DESCRIPTION IMPACT

UNIT

NIT

W

Application of the approach to

CONDITION

>

Application of the approach to simila

WORK BEFORE TABLE

In

Cnangeover time

min 15,53 9,5

9,6

-

MACHINE MO

ROB

O

T

A

R

E

hop

INJECTION MACHINE

O

v

e

r

t

ime reduced by 50%

je

ct

io

n

s

P

2. Identified Scope - Using SWC / SWCT Safety

4 T i ll d N ope-UsingSWC/SWCT

LDC

HA

N

GE

R

A

reduction

ROBOT AREA

4 T i ll

<LOG

Application of the approach to similar processe

s

Identified Scope - Using SWC / SWCT

4 T i ll d N P

NEXT STEP: INJECTION MACHINE TIME REDUCTION Injection Machine Time reduction

Safety best

Injection Machine Time

practice

<LOGO> <LOGO>

Machine waiting time due to:

MOLDCHANGER

M

OLDCHANGER

WORK TABLE

Yokoten to other lines

Next steSpaf:e Audit

Application of the approach to sim ilar processes

VACUUM LAM INATION

FORM ING

Next step:

Auditing

BEST PRACTICE SHARING

Next step:

Injection Machine Time reduction

Safety

Next step:

Safety Auditing Best Practice

Injection M achine Tim e reduction

Auditing

Safety Improvement

32

SAFETY AUDITING

Safety

BEST PRACTICE

Auditing

Data under

PROCESS

-38%) cCoOlleMctioPn E

EGDIEOSNCRAIPLTHIOIGNHL (SIPM: Siginifican TION CHANGE

ment ContrinolcIimdpernotvsempenrtms RiUll:i 0%R) EDUCTIO

InjeIMctPiAoCnT shop AL HIGHLIG n g t h e s t a n d a r d 3 . 6 C O N D3 . I 7

hStoarutrosf Yweaor rkeEnd)of

t h e Ca b n n o a r m n a l g i t y e o v e r 3 . 3 t i m e 3 . 5

EFORE CGM TARG

tain & improve 3.3 3.5

TITIVENESS

IMPACT

IGHTS - TEAM

O V E R T I M E RB

t

n CompetTitiveEnTeAsOs RYU: Parallel

Year Changeover

TS -

UNIT work

ctioBn TIOtiNme reduciton

Changeover

t

ction (TBR)

s

OPR

redu

E(AFGOC)R

ET Downtime reRduEctiSonU(DLIPTO)

e

t

u

p

ime

r

edu

min 15,

UNIT U RUSSIA

Injection shop

Ea Dc k Ug r Co Tu nI Od :

OTA BOSHSOI

53

30 % ch(SeIPcMk: 9,5

RUS

Safe

CONDIS EC8G%Mmin Da

5,93 min (-38%) col

Prepar

T

AR

G

A

GC Internal Use Only.

BEFORE CGM

nloading the previous mol

reduction

LoBaEdiFnAgOGtCRheInEnteCrxnGtamlMUosledO Overtime reT3O.dSYuimOcutTil

AKU RUSSIA

I P M o p e r a t i o Cn sa

ty RU: Checking and

TION

Out-process

1. Studie

ta under 15,5•3PUBLIC ET RESULT lection

i S ni g i gn i f i oc a pn t e r a t i o n s 9 , 6

d TARGET

t nBe dObNSyeHw5O0PKr%Uo c Re sUs

nly.

#

lubricating

公

5

Process

Changeover Time-9.6

libration

開

Loa

din

gt

he n

e

xt mo

ld

9

Prep

Unloading the previous mold

aring

mo

lds f

o

r replacement

,

#

Checking and lubr

3. Simula

SIA RESULT4. Tri

- Video / C

ROBOT AREA

min

9,6

ted New Proce

icating WORK

TARGET RESU

Cnangeover timCe ONDITION

min 15,53

ing molds for replacement

#

Replacing the gri

BENEFIT che alled New Process

9,5 9,6

T Study

ss

AFTER

-5,93

INJECTION MACHINE

LT

ppeRr eplacing the

c ckiSngTAfiTrsUt pSarts

IOBNEFMORAECHI Visualisingtheabnorpmeraltiitoyns COMPETITIVENESS

3.3 pari3ng.3molds for re

Data under

ION CHANGEOVER

RIPTION TOY Unloading the pr

8%) collection

I M P ( AS CI P T M : S i g i n i f i c a n t

ON

hop

Loading the n

%) incidents per million

Ch

Cnangeover time

mCOeM

c

reduction

set

i

hours worked)

9,6

R N

E

OB

OT AREA M

U N I

min

n by 50%

C n

Parallel work

BEFORE CGM

Injection s

V

i

d

e

o

ch

ec

kin

M

O

LDC

HA

/ CT St

15,53 9,5

NGER

CONDITI TARGET

SC

RESULT

PO)

INJECTION MAcChHecINkEing first p 30 %

rtime re

50%

20 min (-50%) i UF)MOLDCHANGER BENEFIT

DITI

ime reduc

t

TABLE

W

i

o

CHAN

O

R

K

g

Replacing the

TABLE

opera

tions

. Studied Process -

udy

WORK

aintaiInNJE&CTIiOmN pMrAoCHvINeE Pre

TIME REDU

T

C

T

I

O

N

up

Ove

r

t

PR

OC

ES

S

DE

INJECTION

IdAing time redu

ON

UNIT

BEFORE

RGET RESULT

other lines

,5 9,6 -5,93

TOYOTA BO6.Y

IMPACT UNISHOKU RU

M a c A h i F n T e T E i mR e r e d u c t i o n 5,93 INJ Eo

dNP

<L <L

eover time min 15,53 ducMtioOnLDCHANGER

T

BEFORE CG

CTION MACHINE

VACUUM FORMING

CONVEYOR

CONVEYOR

LAMINATION

CONVEYOR

CONVEYOR CONVEYOR

CONVEYOR

CONVEYOR

CONVEYOR

CONVEYOR

CONVEYOR

Safety Auditing

Safety Auditing