Page 36 - Toyota Annual Directory 2020-2021

P. 36

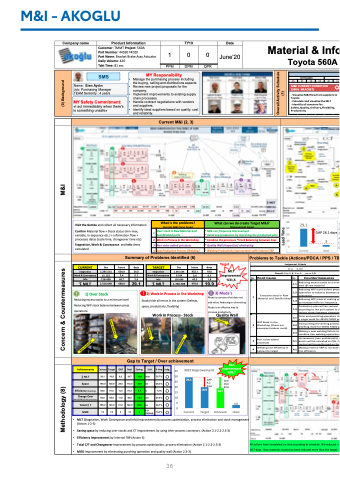

M&I - AKOGLU

Company name

Product Information

TY19

100

PPM DPM QPR

Date

Customer: TMMT Project: 560A

Part Number: 44590 F4020

Part Name: Bracket Brake Assy Actuator Daily Volume: 420

Takt Time: 81 sec

June'20

Material & Inf Toyota 560A

SMS

Name: Eren Aydın

Job: Purchasing Manager TEAM Seniority : 4 years

MY Safety Commitment:

«I act immediately when there's is something unsafe»

MY Responsibility

• Manage the purchasing process including the buying, selling and distributions aspects

• Review new project proposals for the company.

• Implement improvements to existing supply chain processes.

• Handle contract negotiations with vendors and suppliers.

• Identify ideal suppliers based on quality, cost and reliability.

SEPTEMBER

36 37 38 39 40 41

Current M&I (2, 3)

M&I CURRENT CONDITION (560A BRACKET)

- Visualise M&I flow from suppliers to Toyota

- Calculate and visualise the MLT

- Identifiy all concerns for:

Safety, Quality, Delivery, Flexibility, Productivity

40 30 20 10

0

29,1

Visit the Gemba and collect all necessary information

Confirm Material flow + Stock status (min-max, variable, in-sequence etc.) + information flow + processes datas (cycle time, changeover time etc)

Stagnation, Work & Conveyance and Info times calculated

1

2

3

4

What is the problems? (Current M&I Focus Areas)

Over stock in Raw Material and Semifinished parts

Work in Process in the Workshop

Non value added processes

Low Productive Process (Welding)

Summary of Problems Identified (6)

What can we do create Target M&I? (improvement Items)

* Milk-run frequency improvement

* Avoid overproduction by improving the production plan

* Combine the processes *Stock balancing between lines

* Quality Wall (Inspection) eliminating

* Welding Productivity Improvement with internal TBP

Target

MLT Improvement %31,6

Problems to Tackle (Actions/PDCA / PPS / TB

Current

GAP 26,1 days

3

Ideal

CURRENT Sec hours days

Work & Convayance

Info

12.125 3,4 0,1

218.400 60,7 2,5

∑ MLT 2.516.040 698,9 29,1

TARGET Sec hours days

Work & Convayance

Info

9.184 2,6 0,1

156.000 43,3 1,8

∑ MLT 1.720.708 478,0 19,9

No

Root Cause

Judgement Criteria

Stagnation

2.285.515 634,9 26,5

Stagnation

1.555.524 432,1 18,0

O: 2, :1, X:0

Overall:0to2:X,3to4: ,upto4:O

No

Countermeasures

Reducing excess stocks to a mini level @ raw material

1.1

3) Muda's

Muda is a process that does not add value. Reducing or eliminating Muda is an effective way to

Reducing WIP stock before press operation to balance between p operations

1) Over Stock

Reducing excess stocks to a minimum level Reducing WIP stock balance between press operations

2) Work in Process in the Workshop

Stocks hide all errors in the system (Defects, space, productivity, flexiblity)

Work In Process - Stock

increase productivity

Quality Wall

1

Excessive stock in Raw Material and Semifinished

1.2

1.3

Reducing WIP stock at coating pr by increase milk run frequency

Achievements

∑ MLT

Space

Efficiency (Welding) Change Over

(44590F4020 All proceses)

Total C/ T MOD

Current Target GAP

Real Saving

18,7 10,4 112,0 36,0 91,3 6,7 48,0 18,0 122,0 63,0

Unit Days

m2

%

min

sec

# of TM/Shift

% Imp. Judg. 35

35,7% O 30

24,3% O 25 20 7,3% O 15

27,3% O 10 34,1% O 5 14,3% O 0

MLT Improvement

29,1 148,0 84,6 66,0 185,0

19,9 9,2 120,0 28,0 91,0 -6,4 55,0 11,0 124,0 61,0

29,1

Current

GAP 9,2 days

19,9

Target

Gain 10,4 days

18,7

14 12 2 12 2

Achieved

3,0

Ideal

Gap to Target / Over achievement

MLT Improvement %35,7

• MLT (Stagnation, Work Conveyance and Info) Improvement by process optimization, process elimination and stock management (Action 1-2-3)

• Saving space by reducing over stocks and CT improvement by using inter-process conveyors. (Action 2.1-2.2-2.3-3)

• Efficiency Improvement by Internal TBP (Action 4)

• Total C/T and Changeover Improvement by process optimization, process elimination (Action 2.1-2.2-2.3-3)

• MOD Improvement by eliminating punching operation and quality wall (Action 2.3-3)

2

3

4

WIP Stock in the Workshop (There are excessive tandem mold)

Non value added processes

Welding line efficiency is below the target

1.4

2.1

2.2

2.3

3.1

4.1

Production plan will be revised according to the pull system in o reduce stocks between processe

Form and punching operation m a single mold for 44591 F4020 pa

Transporting the drilling process blanking mold for 44592 F4020 p

Making a new welding fixture to combine two welding operations

Unnecessary (non-problematic) c points will be canceled at QW. Fi control will be performed on the

Making internal TBP to increase line efficiency

All actions have completed on time according to schedule. We reduced o

18,7 days. Raw materials stocks has been reduced more than the target.

36

o

1 2 3 4 5 6

m r

s

w

u

S

Methodology (8) Concern & Countermeasures M&I

(0) Background

Lead Time

Overall Activity Schedule (1)