Page 37 - Toyota Annual Directory 2020-2021

P. 37

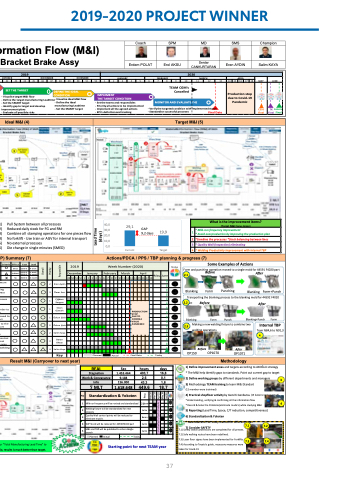

rmation Flow (M&I) Bracket Brake Assy

mum

ing ress

s

to the art

welding

Indirect

No

>1000 € <5000 €

>5000 €

<4 week

>4 week <6 month

>6 month

2

3

1

1

1

2

2

3

4

Eren Aydın

Ömer Avcı

Çiğdem Kargacı

2019-2020 PROJECT WINNER

2019 2020

December

49

50

51

52

1

January

2

3

4

5

February

6

7

8

9

10

March

11

12 13

14

Coach

Erdem POLAT

42 43 44 45 46 47 48 49 50 51 52 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

15

April

16

17

18

May

June

SPM

Erol AKSU

MD

Serdar CANKURTARAN

SMS

Eren AYDIN

Champion

Salim KAYA

OCTOBER NOVEMBER DECEMBER JANUARY FEBRUARY MARCH APRIL

MAY JUNE

SET THE TARGET

DEFINE THE IDEAL

TEAM CGM's Cancelled

MONITOR AND EVALUATE THE

- Verify the targeted condition with implemented status

- Standardise successful proceses Final Date

CONDITION

IMPLEMENT

THE TARGET CONDITION

- Set the teams and responsibles

- Priority all actions to be implemented - Implement all the agreed actions

- KPI's definition and tracking

Production stop due to Covid-19 Pandemic

- Visualise target M&I flow

- Define the target manufacturing Leadtime- Visualise ideal M&I flow

- Set the SMART target

- Identify gap to target and develop improvement plans

- Evaluate all possible risks

- Define the ideal manufacturing Leadtime - Set the SMART target

Ideal M&I (4)

40,0 30,0 20,0 10,0

0,0

29,1

Current

GAP

9,2 days

19,9

Target

Target M&I (5)

CG 6 Final

TK PAN-EU Final Final

) Pull System between all processes

) Reduced daily stock for FG and RM

) Combine all stamping operations for one pieces flow ) No forklift - Use train or AGV for internal transport

) No external processes

) Die change in single minutes (SMED)

What is the improvement items? (Target M&I Focus Areas)

P) Summary (7) Actions/PDCA / PPS / TBP planning & progress (7)

1

2

3

4

* Milk-run frequency improvement

* Avoid overproduction by improving the production plan

*Combine the processes *Stock balancing between lines

* Quality Wall (Inspection) eliminating

* Welding Productivity Improvement with internal TBP

Some Examples of Actions

Form and punching operation moved to a single mold for 44591 F4020 part

After

Criteria

Effect

Direct

Cost

<1000 €

Lead

Week Number (2020)

Status

2.1

Before

Blanking Form Punching Blanking Form+Punch Transporting the blanking process to the blanking mold for 44592 F4020

2.2part Before

After

Form Punch Blanking+Punch Form

Sinan Gürtürk

Özkan İşlek

Özkan İşlek

Salim Kaya

Baran Oktay

Salim Kaya

Key

Planned Actual Final Date Today

RODUCTION STOP

P

DUE TO CORONA VIRUS PANDEMIC

Blanking

2.3 Making a new welding fixture to combine two

Internal TBP

from %84,6 to %91,3

4

welding operations

OP150

Before

OP1070

After

OP1071

Result M&I (Carryover to next year) Methodology

2

3

4

5

Key

REAL Sec hours days

Stagnation

Work & Convayance

Info

Welding fixture will be standardized for new projects

Quality Wall control points will be reduced to eliminate muda's

WIP Stock will be reduced for 44590F4020 part

M&I and TBP will be published to other Akoğlu branch

Planned Actual Today

1.453.464 403,7 16,8

9.184 2,6 0,1

156.000 43,3 1,8

∑ MLT 1.618.648 449,6 18,7

1) Define improvement areas and targets according to AKOĞLU strategy * The M&I help identify gaps to standards. Point out current gap to target 2) Define working groups by different departments and managers

3) Methodology TEAM training to learn M&I Standart

(12 member were trainined)

4) Practical shopfloor activity by Genchi Genbutsu (13 kaizens implemented) *Understanding, verifying & confirming all the information flow

* Record & Solve the Problems(eliminate muda's) while studying M&I

5) Reporting (Lead Time, Space, C/T reduction, competitiveness)

6) Standardization & Yokoten

* New M&I and TBP study started for different areas

7.1 7.2

7.1) Safety switch protections are completed for all presses.

7.2) Safe walking routes have been redefined.

7.3) Laser floor signes have been implemented for Forklifts 7.3 7.4 7.4) According to Toyota's guide, necessary measures were

taken for Covid-19

3

4

No

1

Standardization & Yokoten

Milk run frequency will be revised and standardized

Çiğdem

Salim

Baran

Salim

Salim

7) Consider SAFETY

ur "Total Manufacturing Lead Time" to

So, results is much better than target.

Starting point for next TEAM year

37

o

1 2 3 4 5 6

B

rocess

order to s.

oved to art

p

control inal

e assy.

2019

SHUTDOWN DUE TO COVID-19 PANDEMIC

Feb'20 Mar'20 Apr'20 May'20 Jun'20

Resp.

Overall Priority

Responsible

Lead Time (days)