Page 92 - PRODUCT CATALOGUE_with background music

P. 92

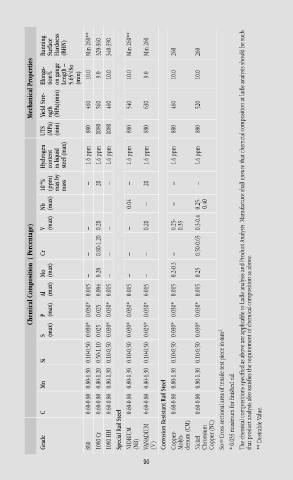

Running Surface Hardness (BHN) Min 260** 320-360 340-390 Min 260** Min 260 260 260

Mechanical Properties Elonga- Yield Stre- tion% on gauge (MPa)(min) Length – 5.65ÖSo (min) 10.0 460 9.0 560 10.0 460 10.0 540 9.0 630 10.0 460 10.0 520

UTS ngth (MPa) (min) 880 1080 1080 880 880 880 880

Hydrogen content in liquid steel (max) 1.6 ppm 1.6 ppm 1.6 ppm 1.6 ppm 1.6 ppm 1.6 ppm 1.6 ppm

10 -4 % (ppm) max by mass – 20 – – 20 – –

(max) 0.04 – – 0.25- 0.40

Nb

(max) V – 0.20 0.80-1.20 – – 0.20 0.25- 0.35 0.3-0.4 0.50-0.65 The chemical compositions specified as above are applicable to Ladle analysis and Product Analysis. Manufacture shall ensure that chemcial composition at ladle analysis should be such

Chemical Composition ( Percentage) Cr Mo Al (max) (max) – – 0.015 0.20 0.004 – – 0.015 – – 0.015 – – 0.015 – 0.2-0.3 0.015 0.25 0.015

(max) P (max) 0.030* 0.030* 0.025 0.025 0.030* 0.030* 0.030* 0.030* 0.030* 0.025* 0.030* 0.030* 0.030* 0.030*

S

0.10-0.50 0.50-1.10 0.10-0.50 0.10-0.50 0.10-0.50 0.10-0.50 0.10-0.50 that product analysis also satisfies the requirement of chemical composition as above.

Si

0.80-1.30 0.80-1.20 0.80-1.30 0.80-1.30 0.80-1.30 0.80-1.30 0.80-1.30

Mn So=Cross sectional area of tensile test piece in mm 2

0.60-0.80 0.60-0.80 0.60-0.80 0.60-0.80 0.60-0.80 0.60-0.80 0.60-0.80

C Corrosion Resistant Rail Steel * 0.035 maximum for finished rail

Grade 880 1080 Cr 1080 HH Special Rail Steel NIOBIUM (NB) VANADIUM (V) Copper- Molyb- denum (CM) Nickel Chromium Copper (NC) ** Desirable Value.

90