Page 5 - CIMAR SHOTCRETE GZ-5E USER MANUAL

P. 5

GEC Shotcrete machine GZ-5E Electric Motor Drive User’s manual

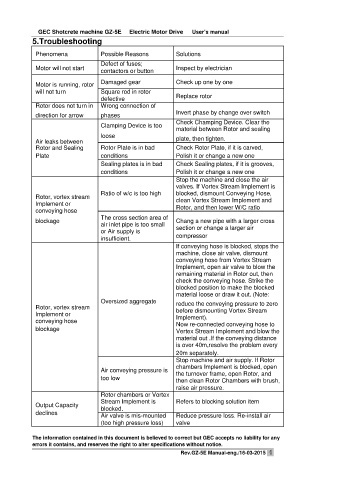

5.Troubleshooting

Phenomena Possible Reasons Solutions

Defect of fuses;

Motor will not start Inspect by electrician

contactors or button

Motor is running, rotor Damaged gear Check up one by one

will not turn Square rod in rotor

defective Replace rotor

Rotor does not turn in Wrong connection of

direction for arrow phases Invert phase by change over switch

Check Champing Device. Clear the

Clamping Device is too material between Rotor and sealing

loose

Air leaks between plate, then tighten.

Rotor and Sealing Rotor Plate is in bad Check Rotor Plate, if it is carved,

Plate conditions Polish it or change a new one

Sealing plates is in bad Check Sealing plates, if it is grooves,

conditions Polish it or change a new one

Stop the machine and close the air

valves. If Vortex Stream Implement is

Ratio of w/c is too high blocked, dismount Conveying Hose,

Rotor, vortex stream clean Vortex Stream Implement and

Implement or Rotor, and then lower W/C ratio

conveying hose

blockage The cross section area of Chang a new pipe with a larger cross

air inlet pipe is too small section or change a larger air

or Air supply is

insufficient. compressor

If conveying hose is blocked, stops the

machine, close air valve, dismount

conveying hose from Vortex Stream

Implement, open air valve to blow the

remaining material in Rotor out, then

check the conveying hose. Strike the

blocked position to make the blocked

material loose or draw it out. (Note:

Oversized aggregate reduce the conveying pressure to zero

Rotor, vortex stream before dismounting Vortex Stream

Implement or Implement).

conveying hose Now re-connected conveying hose to

blockage

Vertex Stream Implement and blow the

material out .If the conveying distance

is over 40m,resolve the problem every

20m separately.

Stop machine and air supply. If Rotor

chambers Implement is blocked, open

Air conveying pressure is the turnover frame, open Rotor, and

too low then clean Rotor Chambers with brush,

raise air pressure.

Rotor chambers or Vortex

Stream Implement is Refers to blocking solution item

Output Capacity blocked.

declines Air valve is mis-mounted Reduce pressure loss. Re-install air

(too high pressure loss) valve

The information contained in this document is believed to correct but GEC accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

Rev.GZ-5E Manual-eng./16-03-2015 4