Page 62 - Global Maintenance Standard - NE_VOct 2020

P. 62

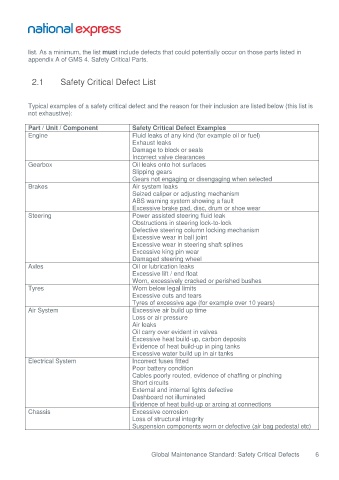

list. As a minimum, the list must include defects that could potentially occur on those parts listed in

appendix A of GMS 4. Safety Critical Parts.

2.1 Safety Critical Defect List

Typical examples of a safety critical defect and the reason for their inclusion are listed below (this list is

not exhaustive):

Part / Unit / Component Safety Critical Defect Examples

Engine Fluid leaks of any kind (for example oil or fuel)

Exhaust leaks

Damage to block or seals

Incorrect valve clearances

Gearbox Oil leaks onto hot surfaces

Slipping gears

Gears not engaging or disengaging when selected

Brakes Air system leaks

Seized caliper or adjusting mechanism

ABS warning system showing a fault

Excessive brake pad, disc, drum or shoe wear

Steering Power assisted steering fluid leak

Obstructions in steering lock-to-lock

Defective steering column locking mechanism

Excessive wear in ball joint

Excessive wear in steering shaft splines

Excessive king pin wear

Damaged steering wheel

Axles Oil or lubrication leaks

Excessive lift / end float

Worn, excessively cracked or perished bushes

Tyres Worn below legal limits

Excessive cuts and tears

Tyres of excessive age (for example over 10 years)

Air System Excessive air build up time

Loss or air pressure

Air leaks

Oil carry over evident in valves

Excessive heat build-up, carbon deposits

Evidence of heat build-up in ping tanks

Excessive water build up in air tanks

Electrical System Incorrect fuses fitted

Poor battery condition

Cables poorly routed, evidence of chaffing or pinching

Short circuits

External and internal lights defective

Dashboard not illuminated

Evidence of heat build-up or arcing at connections

Chassis Excessive corrosion

Loss of structural integrity

Suspension components worn or defective (air bag pedestal etc)

Global Maintenance Standard: Safety Critical Defects 6