Page 6 - QT13442_STI001_CASE_DAEMO_ERKAT

P. 6

MAIN REASONS CX D-SERIES

TO CHOOSE THE D-SERIES CX145D SR

PRODUCTIVITY SPECIFICATIONS

- Faster cycles thanks to improved hydraulic system

- Best-in-class lifting capacity ENGINE SWING

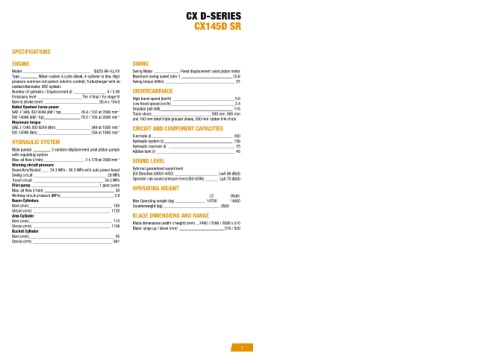

- Increased operating weight for extrastability Model ________________________________ ISUZU AR-4JJ1X Swing Motor ____________ Fixed displacement axial piston motor

Type ________ Water-cooled, 4,cycle diesel, 4-cylinder in line, High Maximum swing speed (min ) ________________________10.6

-1

pressure common rail system (electric control), Turbocharger with air Swing torque (kNm) _________________________________ 37

HIGH VERSATILITY cooled intercooler, SRC system. UNDERCARRIAGE

Number of cylinders / Displacement (l) _______________ 4 / 2.99

- The CASE SR models are the perfect machines for jobsites where space is limited Emissions level _____________________Tier 4 final / Eu stage IV

(for example, road and urban construction) Bore & stroke (mm) __________________________95.4 x 104.9 High travel speed (km/h) _____________________________5.6

Low travel speed (km/h) ______________________________3.4

- 3 available power modes to match customer needs (A, H, SP) Rated flywheel horse power Drawbar pull (kN) __________________________________ 116

SAE J1349, ISO 9249 (kW / hp) _________ 76.4 / 102 at 2000 min -1 Track shoes ____________________________500 mm, 600 mm

ISO 14396 (kW / hp) _________________ 78.5 / 105 at 2000 min -1 and 700 mm steel triple grouser shoes, 500 mm rubber link chain

Maximum torque

HIGH EFFICIENCY SAE J 1349, ISO 9249 (Nm) ________________349 at 1800 min -1 CIRCUIT AND COMPONENT CAPACITIES

- Energy saving system to take advantage of all fuel saving opportunities ISO 14396 (Nm) _________________________356 at 1800 min -1

Fuel tank (l) ______________________________________ 200

HYDRAULIC SYSTEM Hydraulic system (l) ________________________________ 158

Hydraulic reservoir (l) _______________________________ 75

Main pumps ________ 2 variable displacement axial piston pumps Adblue tank (l) _____________________________________ 43

with regulating system

TIER 4 FINAL/STAGE IV ENGINE Max. oil flow (l/min) ___________________ 2 x 129 at 2000 min -1 SOUND LEVEL

Working circuit pressure

- Selective Catalytic Reduction after-treatment system and Diesel Oxidation Catalyst Boom/Arm/Bucket ___ 34.3 MPa - 36.3 MPa with auto power boost External guaranteed sound level

- DPF-free solution saves time and maintenance costs, in addition to delivering a powerful and fuel efficient Swing circuit __________________________________ 28 MPa (EU Directive 2000/14/EC) ____________________ LwA 99 dB(A)

performance Travel circuit _________________________________ 34.3 MPa Operator cab sound pressure level (ISO 6396) ______ LpA 70 dB(A)

Pilot pump ________________________________1 gear pump

Max. oil flow (l/min) _________________________________ 20 OPERATING WEIGHT

Working circuit pressure (MPa) _________________________3.9 LC Blade

HIGH RELIABILITY Boom Cylinders Max Operating weight (kg) ______________ 14700 14800

- Reliability and durability with the new redesigned arm, boom and undercarriage Bore (mm) _______________________________________ 105 Counterweight (kg) ___________________________ 3500

- New high strength casting parts with joined hinge flanges reduce stress and increase durability Stroke (mm) ____________________________________ 1120

Arm Cylinder BLADE DIMENSIONS AND RANGE

Bore (mm) _______________________________________ 115 Blade dimensions (width x height) (mm) _ 2490 / 2590 / 2690 x 570

Stroke (mm) ____________________________________ 1108 Blade range up / down (mm) _____________________ 510 / 520

Bucket Cylinder

SAFE OPERATION Bore (mm) ________________________________________ 95

- ROPS cab and FOPS level II Stroke (mm) _____________________________________ 881

- Standard foldable handrails and guardrails

- Factory fitted travel alarm for greater safety on the jobsite around the machine

- Maintenance points grouped for easy and safe serviceability

COMFORTABLE CAB

- Superior cab structure with ample legroom for the operator

- Fully adjustable workstation

- New high back seat

BETTER VISIBILITY

- Standard rear and side camera

- Optional CASE maximum view monitor (230° rear & side view)

- New optional LED working light package, is more than three times brighter than its halogen equivalent

2 3