Page 40 - Gi_DecJan2020

P. 40

igem news – yppc

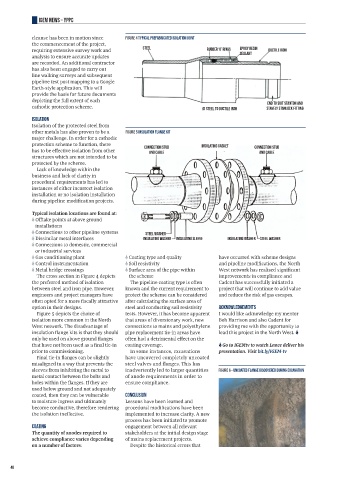

cleanse has been in motion since FIGURE 4 TYPICAL PREFABRICATED ISOLATION JOINT

the commencement of the project,

requiring extensive survey work and steel rubber ‘o’ rings epoxy resin ductile iron

analysis to ensure accurate updates sealant

are recorded. An additional contractor

has also been engaged to carry out

line walking surveys and subsequent

pipeline test post mapping to a Google

Earth-style application. This will

provide the basis for future documents

depicting the full extent of each

end to suit stanton and

cathodic protection scheme. a) steel to ductile iron stavely stanlock fitting

Isolation

Isolation of the protected steel from

other metals has also proven to be a FIGURE 5 INSULATION FLANGE KIT

major challenge. In order for a cathodic

protection scheme to function, there insulating gasket

has to be effective isolation from other connection stud connection stud

and cable

and cable

structures which are not intended to be

protected by the scheme.

Lack of knowledge within the

business and lack of clarity in

procedural requirements has led to

instances of either incorrect isolation

installation or no isolation installation

during pipeline modification projects.

Typical isolation locations are found at:

Offtake points at above ground

installations

Connections to other pipeline systems steel washer

Dissimilar metal interfaces insulating washer insulating sleeve insulating washer steel washer

Connections to domestic, commercial

or industrial services

Gas conditioning plant Coating type and quality have occurred with scheme designs

Control instrumentation Soil resistivity and pipeline modifications, the North

Metal bridge crossings Surface area of the pipe within West network has realised significant

The cross section in Figure 4 depicts the scheme improvements in compliance and

the preferred method of isolation The pipeline coating type is often Cadent has successfully initiated a

between steel and iron pipe. However, known and the current requirement to project that will continue to add value

engineers and project managers have protect the scheme can be considered and reduce the risk of gas escapes.

often opted for a more fiscally attractive after calculating the surface area of

option in their designs. steel and conducting soil resistivity Acknowledgements

Figure 5 depicts the choice of tests. However, it has become apparent I would like acknowledge my mentor

isolation more common in the North that areas of diversionary work, new Bob Harrison and also Cadent for

West network. The disadvantage of connections to mains and polyethylene providing me with the opportunity to

insulation flange kits is that they should pipe replacement tie-in areas have lead this project in the North West.

only be used on above ground flanges often had a detrimental effect on the

that have not been used as a final tie-in coating coverage. Go to IGEMtv to watch Lance deliver his

prior to commissioning. In some instances, excavations presentation. Visit bit.ly/IGEM-tv

Final tie-in flanges can be slightly have uncovered completely uncoated

misaligned in a way that prevents the steel valves and flanges. This has

sleeves from inhibiting the metal to inadvertently led to larger quantities FIGURE 6 - UNCOATED FLANGE DISCOVERED DURING EXCAVATION

metal contact between the bolts and of anode requirements in order to

holes within the flanges. If they are ensure compliance.

used below ground and not adequately

coated, then they can be vulnerable Conclusion

to moisture ingress and ultimately Lessons have been learned and

become conductive, therefore rendering procedural modifications have been

the isolation ineffective. implemented to increase clarity. A new

process has been initiated to promote

Coating engagement between all relevant

The quantity of anodes required to stakeholders at the initial design stage

achieve compliance varies depending of mains replacement projects.

on a number of factors: Despite the historical errors that

40

14/11/2019 16:29

IGEMNews_YPPC.indd 3 14/11/2019 16:29

IGEMNews_YPPC.indd 3