Page 25 - Air Trust

P. 25

24 25

AIR DRYERS PRESSURE VESSELS

Refrigerant Type COMPRESSED AIR/GAS

ATR Series

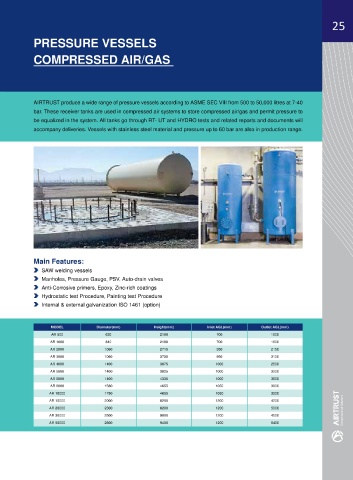

Refrigerant Air Dryers help you to achieve maximum energy savings, while ensuring a continuous supply of dry, AIRTRUST produce a wide range of pressure vessels according to ASME SEC VIII from 500 to 50,000 litres at 7-40

high-quality compressed air. AIRTRUST offers a European brand specially manufactured & designed to help opti- bar. These receiver tanks are used in compressed air systems to store compressed air/gas and permit pressure to

mal and strong performance with a steady pressure dew point with no risk of moisture entering your compressed air be equalized in the system. All tanks go through RT- UT and HYDRO tests and related reports and documents will

system wherever it may be utilized in Iran territory. accompany deliveries. Vessels with stainless steel material and pressure up to 60 bar are also in production range.

Main Features:

Steady pressure dew point (+2°C to +5°C)

Operating ambient temp. (1.5°C to 45°C)

Evaporator (brazed plate S.S / Aluminum)

Max. operating pressure up to 16 bar

Compressor (Emerson/Copeland/Tecumseh)

Electronic drain or programmable timer

Easy installation / maintenance

Reduced energy consumption

IP 55 protection class

Main Features:

SAW welding vessels

Manholes, Pressure Gauge, PSV, Auto-drain valves

Anti-Corrosive primers, Epoxy, Zinc-rich coatings

MODEL M 3 /Min L(mm) W (mm) H (mm) DN Kg W

ATR-20 0.33 485 352 499 G 3/8” BSP-F 25 135 Hydrostatic test Procedure, Painting test Procedure

ATR-35 0.58 485 352 499 G 3/8” BSP-F 25 135 Internal & external galvanization ISO 1461 (option)

ATR-50 0.83 485 352 499 G 3/4” BSP-F 26 180

ATR-75 1.25 485 352 499 G 3/4” BSP-F 27 250

ATR-100 1.67 485 352 499 G 3/4” BSP-F 32 320 MODEL Diameter(mm) Height(mm) Inlet AGL(mm) Outlet AGL(mm)

ATR-140 2.33 552 357 684 G 1” BSP-F 50 480 AR 500 630 2100 700 1600

ATR-180 3.00 552 357 684 G 1” BSP-F 52 500 AR 1000 840 2100 700 1600

ATR-235 3.92 552 357 684 G 1” BSP-F 56 700 AR 2000 1060 2715 950 2150

ATR-300 5.00 589 496 827 G 11/4” BSP-F 84 950 AR 3000 1060 3735 950 3100

ATR-380 6.33 589 496 827 G 11/4” BSP-F 90 1.080 AR 4000 1400 3075 1000 2500

ATR-480 8.00 589 496 827 G 11/2” BSP-F 99 1.200 AR 5000 1400 3825 1000 3200

ATR-600 10.00 710 491 973 G 2” BSP-F 110 1.250 AR 6000 1400 4335 1000 3800

ATR-750 12.50 710 491 973 G 2” BSP-F 120 1.600 AR 8000 1580 4655 1050 3900

ATR-950 15.83 710 491 973 G 2” BSP-F 150 2.100 AR 10000 1750 4655 1050 3900

ATR-1150 19.17 856 663 1.534 G 21/2” BSP-F 250 2.200 AR 15000 2000 8200 1200 4200

ATR-1300 21.67 856 663 1.534 G 21/2” BSP-F 280 2.600 AR 20000 2300 8200 1200 5000

ATR-1500 25.00 856 663 1.534 G 21/2” BSP-F 290 2.700 AR 30000 2500 9000 1200 4500

ATR-1900 31.67 856 663 1.534 G 21/2” BSP-F 310 4.000 AR 50000 2800 9400 1200 6400

* Bigger sizes available up to ATR-13200 (220 m /min)

3