Page 9 - Digital Binder_Neat

P. 9

707 Swan Drroe

Mukwcmago, WT 53149

800-425-2214

tel 262-363-9877 fax 262-363-9879

wiUlv.bo11.stone.com iufo@lxmstone.com

TECHNICAL DATA SHEET

FILE UNDER DIV. 4

Anchor Epoxy TM

Product Description

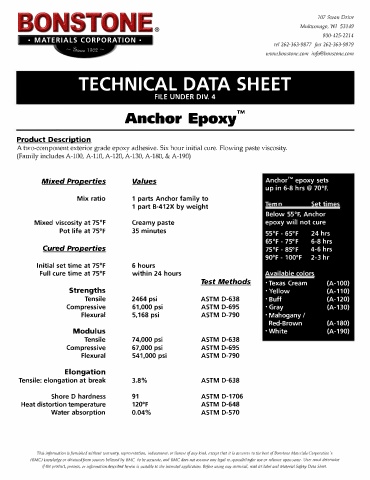

A two-component exterior grade epoxy adhesive. Six hour initial cure. Flowing paste viscosity.

(Family includes A-100, A-110, A-120, A-130, A-180, & A-190)

Mixed Properties Values Anchor"' epoxy sets

up in 6-8 hrs @ 70 F.

°

Mix ratio 1 parts Anchor family to

1 part B-412X by weight Tern Set times

Below 55 F, Anchor

°

Mixed viscosity at 75 F Creamy paste epoxy will not cure

°

°

Pot life at 75 F 35 minutes ss F - 65 F 24 hrs

°

°

°

°

65 F - 75 F 6-8 hrs

Cured Properties 75 F - 85 F 4-6 hrs

°

°

°

°

90 F - 100 F 2-3 hr

Initial set time at 75 F 6 hours

°

°

Full cure time at 75 F within 24 hours Available colors

Test Methods • Texas Cream (A-100)

Strengths ·Yellow (A-110)

Tensile 2464 psi ASTM D-638 • Buff (A-120)

Compressive 61,000 psi ASTM D-695 • Gray (A-130)

Flexural 5,168 psi ASTM D-790 ·Mahogany/

Red-Brown (A-180)

Modulus ·White (A-190)

Tensile 74,000 psi ASTM D-638

Compressive 67,000 psi ASTM D-695

Flexural 541,000 psi ASTM D-790

Elongation

Tensile: elongation at break 3.8% ASTM D-638

Shore D hardness 91 ASTM D-1706

°

Heat distortion temperature 120 F ASTM D-648

Water absorption 0.04% ASTM D-570

TM:, infomwfion � fum�lit'd wir/Jout warranty, �pr,smfafio11, i11ducemeut, or Iice,1sr. of ,my ki11d. exce11t tlrat it is occuraJ1• to rl,r. best ef Bc,rstoue Mafrrinls Cor1ioratio11's

(BMC> browledg , : or (M1taintd from :-OUl\ . l'S Mie--,xd l;,y BMC to� �Tumft'. arrd BMC d«s not assm11e any l(gaI iy._,po11�l1i/i1y fer use or reliaJ1u upou sour,:. User mu..,r drlt'm1i11e

1f tl1f ptodud, procm, or i11fer111ation de.st:ri[)ed lrerei11 Is :.uirablt> to tlit lutmdt>d application. Before using a11y chm1ial.l, m,d its laM an,1 Material Stlfrty Data Shetl,