Page 4 - GLASGRID GLASPAVE BROCHURE

P. 4

––––

Special Specification 3032

Reinforced Paving Mat for for Asphalt Pavement Overlays

1 DESCRIPTION

Furnish and and place a a a a a a a a a a a a a a a a a a a high strength paving mat mat within the pavement structure as as a a a a a a a a a a a a a a a a a a a moisture barrier and and stress relieving interlayer The HS Paving mat mat must have an an an elastomeric polymer coating coating bitumen coatings are not eligible for consideration 1 1 1 1 Quality Control Before installing the the the the the paving paving mat mat arrange a a a a a a a a a a a a a a a a a a a a a meeting at at at at at the the the the the site with the the the the the manufacturer’s representative and where applicable the the the the the the the paving paving mat mat installer Notify the the the the the the the Engineer at at at at at least 3 days in in in in in in in in in advance of of the the time of of the the meeting A manufacturer’s representative must be present present at at at at minimum for the the the the first day of of installation of of the the the the engineered paving mat and available thereafter upon request by the the the Engineer 2

MATERIALS

2

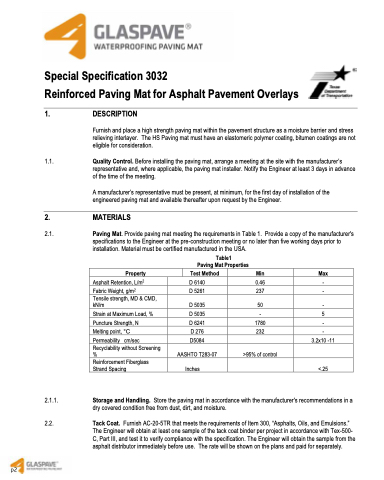

1 1 Paving Mat Provide Provide paving mat meeting meeting the the the the requirements in in in in in in in Table 1 1 Provide Provide a a a a a a a a a a a a a copy of the the the the manufacturer's specifications to to the the the the the Engineer at at at at at at at the the the the the pre-construction meeting meeting or or or no later than five working days prior to to installation Material must be certified manufactured in in in in the the the USA 3032

Table1 Paving Mat Properties

Test Method

D 6140 D 5261

D 5035

Strain at Maximum Load %

Puncture Strength N

D 6241 Melting point °C D 276

Permeability cm/sec D5084 Recyclability without Screening

%

AASHTO T283-07 Reinforcement Fiberglass

Strand Spacing Inches

Property

Asphalt Retention L/m2

Fabric Weight g/m2

Tensile strength MD MD & CMD kN/m

Min Max 0 46 - 237 - 50 - -5

D 5035

1780 232

>95% of control

- - 3 2x10 -11

< 25

2

1 1 1 1 Storage and and and Handling Store the the paving mat in in in in accordance with the the manufacturer's recommendations in in in in a a a a a a a a a a a a dry covered condition free from dust dirt and and and moisture 2

2

2

2

2

2

Tack Coat Furnish AC-20-5TR that meets the the requirements of of Item 300 “Asphalts Oils and Emulsions ” The The Engineer Engineer will will obtain obtain at at at at at least one sample sample of of the the the the the tack coat binder per project in in in in in in accordance with with Tex-500- C Part III and and test it it it to to verify compliance with with the the the the the specification The The The Engineer Engineer will will will obtain obtain the the the the the sample sample from the the the the the asphalt distributor immediately before use The The rate rate will will be be shown on on the the the plans and and paid for for separately p2