Page 7 - MMT CATALOG

P. 7

SPM: CAGE MILLING 6

(Horizontal Milling SPM: HYD/Servo -PLC)

SPM Cage Milling Machine is used

for pocketing on workpiece for

special purpose application such as

pocketing of brass cage for spherical

roller requirement. Vertical Milling

machine for such application may be

very costly compare to our cage

milling machine.

Key features of SPM: Cage Milling

Machine Are

Cartridge type Milling Spindle

with greased pack ISO-P4 Class

matched pair bearing and comes

with ISO40 Collet bore in Shaft for

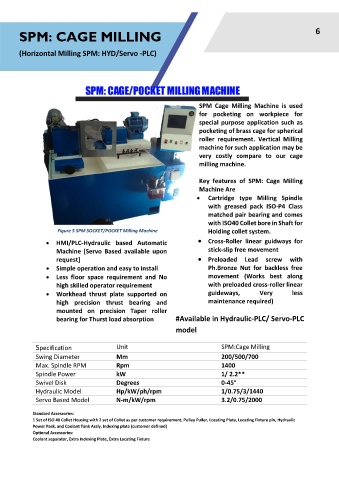

Figure 5 SPM SOCKET/POCKET Milling Machine Holding collet system.

HMI/PLC-Hydraulic based Automatic Cross-Roller linear guidways for

Machine [Servo Based available upon stick-slip free movement

request] Preloaded Lead screw with

Simple operation and easy to install Ph.Bronze Nut for backless free

Less floor space requirement and No movement (Works best along

high skilled operator requirement with preloaded cross-roller linear

Workhead thrust plate supported on guideways, Very less

high precision thrust bearing and maintenance required)

mounted on precision Taper roller

bearing for Thurst load absorption #Available in Hydraulic-PLC/ Servo-PLC

model

Specification Unit SPM:Cage Milling

Swing Diameter Mm 200/500/700

Max. Spindle RPM Rpm 1400

Spindle Power kW 1/ 2.2**

Swivel Disk Degrees 0-45°

Hydraulic Model Hp/kW/ph/rpm 1/0.75/3/1440

Servo Based Model N-m/kW/rpm 3.2/0.75/2000

Standard Accessories:

1 Set of ISO 40 Collet Housing with 2 set of Collet as per customer requirement, Pulley Puller, Locating Plate, Locating Fixture pin, Hydraulic

Power Pack, and Coolant Tank Assly, Indexing plate (customer defined)

Optional Accessories:

Coolant separator, Extra Indexing Plate, Extra Locating Fixture