Page 6 - BROCHURE 3

P. 6

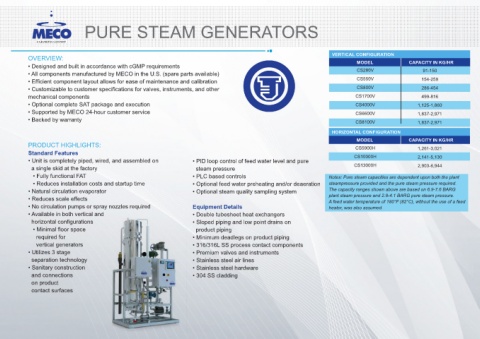

PURE STEAM GENERATORS

VERTICAL CONFIGURATION

OVERVIEW:

MODEL CAPACITY IN KG/HR

• Designed and built in accordance with cGMP requirements

CS280V 91-150

• All components manufactured by MECO in the U.S. (spare parts available)

CS550V 154-259

• Efficient component layout allows for ease of maintenance and calibration

• Customizable to customer specifications for valves, instruments, and other CS800V 286-454

mechanical components CS1700V 499-816

• Optional complete SAT package and execution CS4000V 1,125-1,860

• Supported by MECO 24-hour customer service CS6600V 1,837-2,971

• Backed by warranty

CS8100V 1,837-2,971

HORIZONTAL CONFIGURATION

MODEL CAPACITY IN KG/HR

PRODUCT HIGHLIGHTS:

CS5900H 1,261-3,021

Standard Features

CS10000H 2,141-5,130

• Unit is completely piped, wired, and assembled on • PID loop control of feed water level and pure

CS13000H 2,903-6,944

a single skid at the factory steam pressure

• Fully functional FAT • PLC based controls Notes: Pure steam capacities are dependent upon both the plant

• Reduces installation costs and startup time • Optional feed water preheating and/or deaeration steampressure provided and the pure steam pressure required.

• Natural circulation evaporator • Optional steam quality sampling system The capacity ranges shown above are based on 6.9-7.6 BARG

plant steam pressure and 2.8-4.1 BARG pure steam pressure.

• Reduces scale effects

A feed water temperature of 180°F (82°C), without the use of a feed

• No circulation pumps or spray nozzles required Equipment Details heater, was also assumed.

• Available in both vertical and • Double tubesheet heat exchangers

horizontal configurations • Sloped piping and low point drains on

• Minimal floor space product piping

required for • Minimum deadlegs on product piping

vertical generators • 316/316L SS process contact components

• Utilizes 3 stage • Premium valves and instruments

separation technology • Stainless steel air lines

• Sanitary construction • Stainless steel hardware

and connections • 304 SS cladding

on product

contact surfaces