Page 65 - Barkev Product Catalogue

P. 65

Scapa Complementary Range

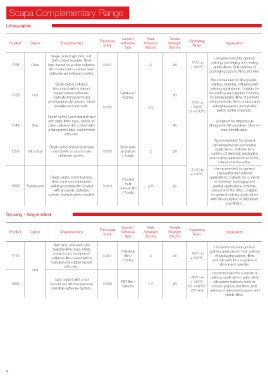

Lithographic

Product Colour Characteristics Thickness Carrier / Peel Tensile Operating Application

1100 Clear (mm) Adhesive Adhesion Strength Temp.

1129 (N/cm)

1140 type (N/cm)

Single-sided high tack, anti- 2 Recommended for general

static, hand tearable, filmic

tape based on a clear cellulose 0.047 48 -15°C to splicing, packaging and sealing

film coated with a rubber resin +100°C applications. Butt splicing of

adhesive and release coated.

packaging papers, films and foils.

Recommended for lithographic,

Single-sided cellulose edging, masking, stripping and

film coated with a solvent splicing applications. Suitable for

Red based rubber adhesive. Cellulose / 40 the printing and graphics industry,

Optically transparent and Rubber for photographic films. It protects

photographically opaque. Hand -10°C to orthochromatic films, contact and

tearable and anti-static. 0.045 2.2 +100°C enlarging papers and printing

ST +130°C plates during exposure.

Single-sided, hand tearable and Designed for stripping up

anti-static filmic tape, based on 36 lithographic film positives. Blue for

Blue clear cellulose film coated with

a transparent blue, rubber/resin easy identification.

adhesive.

Recommended for general

Single-sided crystal clear tape Clear poly- gift wrapping and packaging

coated with a cured acrylic propylene

1250 Ultra clear adhesive system. 0.045 / Acrylic 2 28 applications. Suitable for a

varietey of domestic packaging

and sealing applications at home,

school or in the office.

Single-sided, hand tearable, -15°C to Recommended for general

filmic tape and translucent +110°C packaging and splicing

cellulose acetate film coated

with an acrylic adhesive Frosted applications. Suitable for a variety

system. Invisible when applied. matt

1919 of domestic packaging and

acetate film

Translucent 0.054 / Acrylic 2.6 35 sealing applications at home,

school or in the office. Suitable

for general splicing applications

with the exception of siliconised

substrates.

Splicing - Single sided

Product Colour Characteristics Thickness Carrier / Peel Tensile Operating Application

(mm) Adhesive Adhesion Strength Temp.

High tack, anti-static and (N/cm)

tearable filmic tape which type (N/cm)

consists of a transparent

cellulose film coated with a 3 Recommended for general

red pigment, rubber based

1112 0.057 Cellulose 36 -50°C to splicing applications. Butt splicing

1650 adhesive. film / +100°C of packaging papers, films

Rubber and foils with the exception of

siliconised materials.

Red Recommended for a variety of

Tape coated with a red -50°C to splicing applications, particularly

translucent silicone pressure

sensitive adhesive system. 0.048 PET film / 2.8 40 +130°C siliconised surfaces such as

Silicone

ST +180°C release papers and films. Butt

(20 min) splicing of siliconised papers and

plastic films.

9