Page 123 - Flipbook_SolidDesignSoutheast2020

P. 123

Model 260 Series Weigh Belt Weighers/Feeders

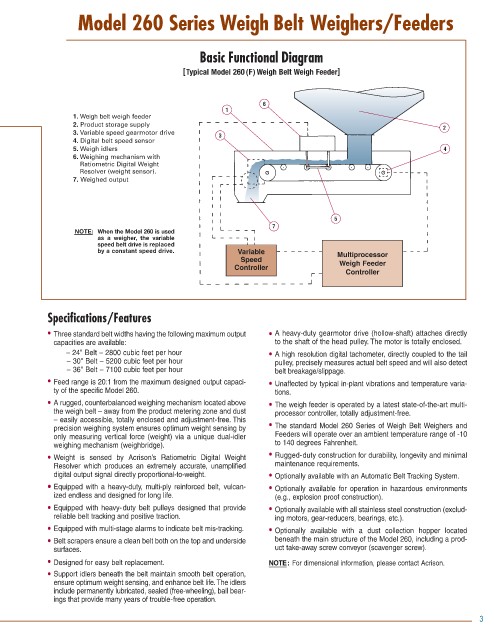

Basic Functional Diagram

[Typical Model 260(F) Weigh Belt Weigh Feeder]

6

1

1. Weigh belt weigh feeder

2. Product storage supply

2

3. Variable speed gearmotor drive

3

4. Digital belt speed sensor

5. Weigh idlers 4

6. Weighing mechanism with

Ratiometric Digital Weight

Resolver (weight sensor).

7. Weighed output

5

7

NOTE: When the Model 260 is used

as a weigher, the variable

speed belt drive is replaced

by a constant speed drive. Variable Multiprocessor

Speed

Controller Weigh Feeder

Controller

Specifications/Features

• Three standard belt widths having the following maximum output • A heavy-duty gearmotor drive (hollow-shaft) attaches directly

capacities are available: to the shaft of the head pulley. The motor is totally enclosed.

– 24" Belt – 2800 cubic feet per hour • A high resolution digital tachometer, directly coupled to the tail

– 30" Belt – 5200 cubic feet per hour pulley, precisely measures actual belt speed and will also detect

– 36" Belt – 7100 cubic feet per hour belt breakage/slippage.

• Feed range is 20:1 from the maximum designed output capaci- • Unaffected by typical in-plant vibrations and temperature varia-

ty of the specific Model 260. tions.

• A rugged, counterbalanced weighing mechanism located above • The weigh feeder is operated by a latest state-of-the-art multi-

the weigh belt – away from the product metering zone and dust processor controller, totally adjustment-free.

– easily accessible, totally enclosed and adjustment-free. This

precision weighing system ensures optimum weight sensing by • The standard Model 260 Series of Weigh Belt Weighers and

only measuring vertical force (weight) via a unique dual-idler Feeders will operate over an ambient temperature range of -10

weighing mechanism (weighbridge). to 140 degrees Fahrenheit.

• Weight is sensed by Acrison’s Ratiometric Digital Weight • Rugged-duty construction for durability, longevity and minimal

Resolver which produces an extremely accurate, unamplified maintenance requirements.

digital output signal directly proportional-to-weight. • Optionally available with an Automatic Belt Tracking System.

• Equipped with a heavy-duty, multi-ply reinforced belt, vulcan- • Optionally available for operation in hazardous environments

ized endless and designed for long life. (e.g., explosion proof construction).

• Equipped with heavy-duty belt pulleys designed that provide • Optionally available with all stainless steel construction (exclud-

reliable belt tracking and positive traction. ing motors, gear-reducers, bearings, etc.).

• Equipped with multi-stage alarms to indicate belt mis-tracking. • Optionally available with a dust collection hopper located

• Belt scrapers ensure a clean belt both on the top and underside beneath the main structure of the Model 260, including a prod-

surfaces. uct take-away screw conveyor (scavenger screw).

• Designed for easy belt replacement. NOTE: For dimensional information, please contact Acrison.

• Support idlers beneath the belt maintain smooth belt operation,

ensure optimum weight sensing, and enhance belt life.The idlers

include permanently lubricated, sealed (free-wheeling), ball bear-

ings that provide many years of trouble-free operation.

3