Page 1403 - Flipbook_SolidDesignSoutheast2020

P. 1403

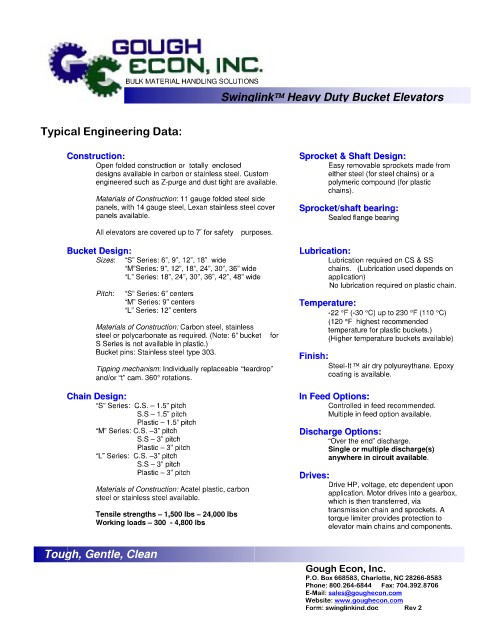

BULK MATERIAL HANDLING SOLUTIONS

Heavy Duty Bucket Elevators

Swinglink

Typical Engineering Data:

C Co on ns st tr ru uc ct ti io on n: : S Sp pr ro oc ck ke et t & & S Sh ha af ft t D De es si ig gn n: :

Open folded construction or totally enclosed Easy removable sprockets made from

designs available in carbon or stainless steel. Custom either steel (for steel chains) or a

engineered such as Z-purge and dust tight are available. polymeric compound (for plastic

chains).

Materials of Construction: 11 gauge folded steel side

panels, with 14 gauge steel, Lexan stainless steel cover S Sp pr ro oc ck ke et t/ /s sh ha af ft t b be ea ar ri in ng g: :

panels available. S Se ea al le ed d f fl la an ng ge e b be ea ar ri in ng g

All elevators are covered up to 7’ for safety purposes.

B Bu uc ck ke et t D De es si ig gn n: : L Lu ub br ri ic ca at ti io on n: :

Sizes: “S” Series: 6”, 9”, 12”, 18” wide Lubrication required on CS & SS

“M”Series: 9”, 12”, 18”, 24”, 30”, 36” wide chains. (Lubrication used depends on

“L” Series: 18”, 24”, 30”, 36”, 42”, 48” wide application)

No lubrication required on plastic chain.

Pitch: “S” Series: 6” centers

“M” Series: 9” centers T Te em mp pe er ra at tu ur re e: :

“L” Series: 12” centers -22 °F (-30 °C) up to 230 °F (110 °C)

(120 °F highest recommended

Materials of Construction: Carbon steel, stainless temperature for plastic buckets.)

steel or polycarbonate as required. (Note: 6” bucket for (Higher temperature buckets available)

S Series is not available in plastic.)

Bucket pins: Stainless steel type 303. Finish:

Tipping mechanism: Individually replaceable “teardrop” Steel-It air dry polyureythane. Epoxy

and/or “t” cam. 360° rotations. coating is available.

C Ch ha ai in n D De es si ig gn n: : I In n F Fe ee ed d O Op pt ti io on ns s: :

“S” Series: C.S. – 1.5” pitch Controlled in feed recommended.

S.S – 1.5” pitch Multiple in feed option available.

Plastic – 1.5” pitch

“M” Series: C.S. –3” pitch D Di is sc ch ha ar rg ge e O Op pt ti io on ns s: :

S.S – 3” pitch “Over the end” discharge.

Plastic – 3” pitch Single or multiple discharge(s)

“L” Series: C.S. –3” pitch anywhere in circuit available.

S.S – 3” pitch

Plastic – 3” pitch D Dr ri iv ve es s: :

Drive HP, voltage, etc dependent upon

Materials of Construction: Acatel plastic, carbon application. Motor drives into a gearbox,

steel or stainless steel available. which is then transferred, via

transmission chain and sprockets. A

Tensile strengths – 1,500 lbs – 24,000 lbs torque limiter provides protection to

Working loads – 300 - 4,800 lbs elevator main chains and components.

Tough, Gentle, Clean

Gough Econ, Inc.

P.O. Box 668583, Charlotte, NC 28266-8583

Phone: 800.264-6844 Fax: 704.392.8706

E-Mail: sales@goughecon.com

Form: swinglinkind.doc Rev 2

Website: www.goughecon.com