Page 2767 - Flipbook_SolidDesignSoutheast2020

P. 2767

FEATURES APPLICATIONS OPTIONS

n Grinds friable materials n Agricultural Chemicals n ntake hoppers and rotary valves n Finishes to FDA, pharmaceutical,

I

to narrow size ranges; n Ceramic Filter Media to meter material into mill and other sanitary or industrial

de-agglomerates lumpy n Custom transitions for gravity standards: #304 or #316

materials n Chalks discharge or pneumatic stainless steel with #2B

n Simple design —only one n Chemicals (Inorganic) collection (standard) or #4 finish,

moving part contacting material n Coal n Sound deadening enclosures as well as carbon steel

n Air-swept principle of operation n Dry Clay n Explosion proof motors and n Variable-speed electronic

keeps material cool n Filter Cake electricals controls for adjusting rotor speed

n Easy to clean and sanitize n Fish Food n Removable rotor disc for critical n Speed switches

n Five rows of intermeshing n Flour (wheat, rice and others) sanitary applications n Stainless steel base frames

impact pins n Foods n Single or double davit arms for n Magnets to prevent tramp

n Safety interlocked access door/ n Friable Minerals swinging stator disc and/or rotor metals from entering mill

stator disc hinges open for n Friable Resins/Polymers disc away from machine chamber

unrestricted access to all internal n Hardened D2, M2, 440 and n Ports for cooling with liquid

material contact surfaces n Gelatin TiN-coated pins nitrogen or purging with

n Vertical orientation of mill n Grains n nternal welds with minimum inert gas

I

housing offers easier cleaning n Gypsum 0.25 in. (6.4 mm) radii ground n Filtered collection hoppers

and sanitizing than horizontal n Herbicides, Pesticides and polished from 80 grit up (smaller systems)

designs and Fungicides to 240 grit to prevent material

n Precision machined housing n Pharmaceuticals entrapment

and discs

n Pigments

n Easy-flow inlet elbow

n Polymers

n Design efficiency produces n Powdered and Coarse Sugar

high throughput rates per

horsepower/kilowatt n Powdered Lecithin

n 5 to 125 hp (4 to 93 kw) n Powdered Metals

inverter-capable motors n Propanil Flakes

n Multiple V-Belt and sheave n Resins

drive arrangements. Direct n Salt

drive on CIM-18 only.

n Sodium Acetate Flakes

n Spices

n Starch

n Sugar

n Urea/MAP/DAP

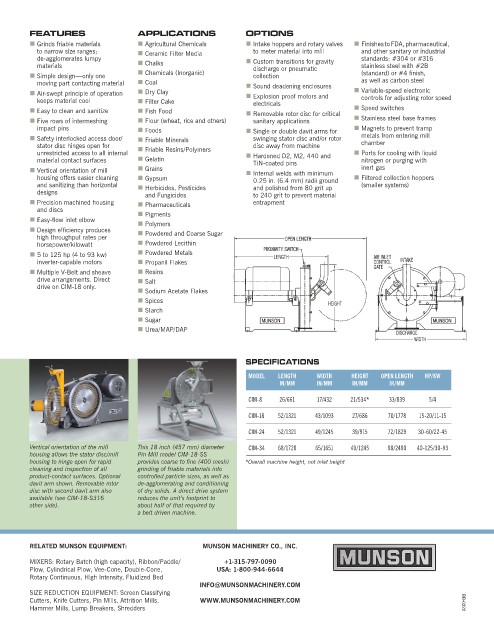

SPECIFICATIONS

MODEL LENGTH WIDTH HEIGHT OPEN LENGTH HP/KW

IN/MM IN/MM IN/MM IN/MM

CIM-8 26/661 17/432 21/534* 33/839 5/4

CIM-18 52/1321 43/1093 27/686 70/1778 15-20/11-15

CIM-24 52/1321 49/1245 39/915 72/1829 30-60/22-45

Vertical orientation of the mill This 18 inch (457 mm) diameter CIM-34 68/1728 65/1651 49/1245 98/2490 40-125/30-93

housing allows the stator disc/mill Pin Mill model CIM-18-SS

housing to hinge open for rapid provides coarse to fine (400 mesh) *Overall machine height, not inlet height

cleaning and inspection of all grinding of friable materials into

product-contact surfaces. Optional controlled particle sizes, as well as

davit arm shown. Removable rotor de-agglomerating and conditioning

disc with second davit arm also of dry solids. A direct drive system

available (see CIM-18-S316 reduces the unit’s footprint to

other side). about half of that required by

a belt driven machine.

RELATED MUNSON EQUIPMENT: MUNSON MACHINERY CO., INC.

MIXERS: Rotary Batch (high capacity), Ribbon/Paddle/ +1-315-797-0090

Plow, Cylindrical Plow, Vee-Cone, Double-Cone, USA: 1-800-944-6644

Rotary Continuous, High Intensity, Fluidized Bed

INFO@MUNSONMACHINERY.COM

SIZE REDUCTION EQUIPMENT: Screen Classifying

Cutters, Knife Cutters, Pin Mills, Attrition Mills, WWW.MUNSONMACHINERY.COM BB-0322

Hammer Mills, Lump Breakers, Shredders

BB-0322_PinMillCutSheet_20160413.indd 2 4/22/16 11:51 AM