Page 2775 - Flipbook_SolidDesignSoutheast2020

P. 2775

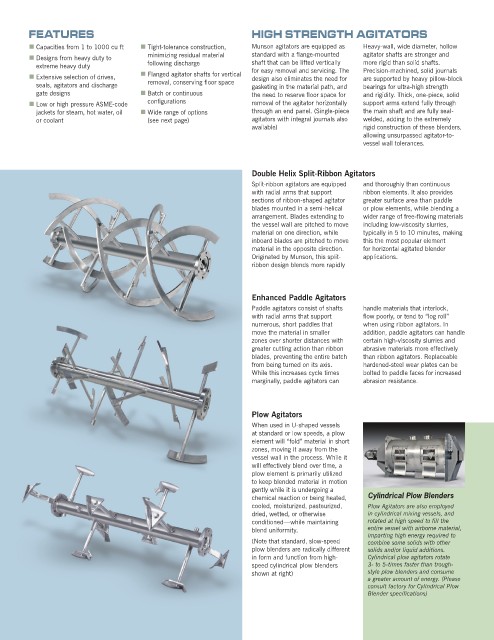

FEATURES HIGH STRENGTH AGITATORS

n Capacities from 1 to 1000 cu ft n Tight-tolerance construction, Munson agitators are equipped as Heavy-wall, wide diameter, hollow

n Designs from heavy duty to minimizing residual material standard with a flange-mounted agitator shafts are stronger and

extreme heavy duty following discharge shaft that can be lifted vertically more rigid than solid shafts.

Precision-machined, solid journals

for easy removal and servicing. The

n Extensive selection of drives, n Flanged agitator shafts for vertical design also eliminates the need for are supported by heavy pillow-block

seals, agitators and discharge removal, conserving floor space gasketing in the material path, and bearings for ultra-high strength

gate designs n Batch or continuous the need to reserve floor space for and rigidity. Thick, one-piece, solid

n Low or high pressure ASME-code configurations removal of the agitator horizontally support arms extend fully through

jackets for steam, hot water, oil n Wide range of options through an end panel. (Single-piece the main shaft and are fully seal-

or coolant (see next page) agitators with integral journals also welded, adding to the extremely

available) rigid construction of these blenders,

allowing unsurpassed agitator-to-

vessel wall tolerances.

Double helix split-ribbon agitators

Split-ribbon agitators are equipped and thoroughly than continuous

with radial arms that support ribbon elements. It also provides

sections of ribbon-shaped agitator greater surface area than paddle

blades mounted in a semi-helical or plow elements, while blending a

arrangement. Blades extending to wider range of free-flowing materials

the vessel wall are pitched to move including low-viscosity slurries,

material on one direction, while typically in 5 to 10 minutes, making

inboard blades are pitched to move this the most popular element

material in the opposite direction. for horizontal agitated blender

Originated by Munson, this split- applications.

ribbon design blends more rapidly

enhanced Paddle agitators

Paddle agitators consist of shafts handle materials that interlock,

with radial arms that support flow poorly, or tend to “log roll”

numerous, short paddles that when using ribbon agitators. In

move the material in smaller addition, paddle agitators can handle

zones over shorter distances with certain high-viscosity slurries and

greater cutting action than ribbon abrasive materials more effectively

blades, preventing the entire batch than ribbon agitators. Replaceable

from being turned on its axis. hardened-steel wear plates can be

While this increases cycle times bolted to paddle faces for increased

marginally, paddle agitators can abrasion resistance.

Plow agitators

When used in U-shaped vessels

at standard or low speeds, a plow

element will “fold” material in short

zones, moving it away from the

vessel wall in the process. While it

will effectively blend over time, a

plow element is primarily utilized

to keep blended material in motion

gently while it is undergoing a

chemical reaction or being heated, Cylindrical Plow Blenders

cooled, moisturized, pasteurized, Plow Agitators are also employed

dried, wetted, or otherwise in cylindrical mixing vessels, and

conditioned—while maintaining rotated at high speed to fill the

blend uniformity. entire vessel with airborne material,

imparting high energy required to

(Note that standard, slow-speed combine some solids with other

plow blenders are radically different solids and/or liquid additions.

in form and function from high- Cylindrical plow agitators rotate

speed cylindrical plow blenders 3- to 5-times faster than trough-

shown at right) style plow blenders and consume

a greater amount of energy. (Please

consult factory for Cylindrical Plow

Blender specifications)