Page 2787 - Flipbook_SolidDesignSoutheast2020

P. 2787

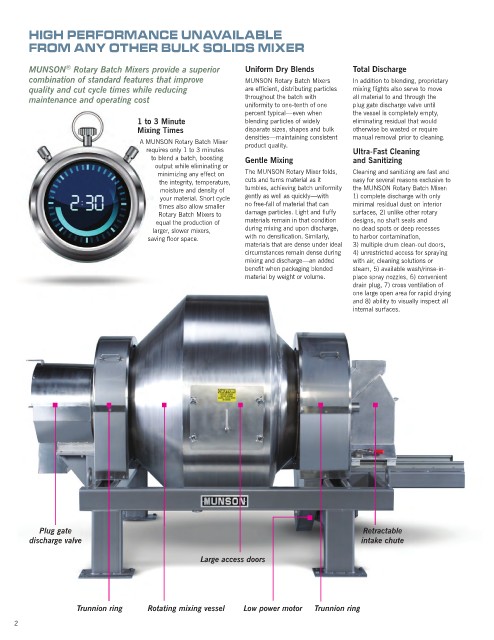

HIGH PERFORMANCE UNAVAILABLE

FROM ANY OTHER BULK SOLIDS MIXER

®

MUNSON Rotary Batch Mixers provide a superior Uniform Dry Blends Total Discharge

combination of standard features that improve MUNSON Rotary Batch Mixers In addition to blending, proprietary

quality and cut cycle times while reducing are efficient, distributing particles mixing flights also serve to move

maintenance and operating cost throughout the batch with all material to and through the

uniformity to one-tenth of one

plug gate discharge valve until

percent typical—even when the vessel is completely empty,

1 to 3 Minute blending particles of widely eliminating residual that would

Mixing Times disparate sizes, shapes and bulk otherwise be wasted or require

densities—maintaining consistent manual removal prior to cleaning.

A MUNSON Rotary Batch Mixer product quality.

requires only 1 to 3 minutes Ultra-Fast Cleaning

to blend a batch, boosting Gentle Mixing and Sanitizing

output while eliminating or

minimizing any effect on The MUNSON Rotary Mixer folds, Cleaning and sanitizing are fast and

the integrity, temperature, cuts and turns material as it easy for several reasons exclusive to

moisture and density of tumbles, achieving batch uniformity the MUNSON Rotary Batch Mixer:

your material. Short cycle gently as well as quickly—with 1) complete discharge with only

times also allow smaller no free-fall of material that can minimal residual dust on interior

Rotary Batch Mixers to damage particles. Light and fluffy surfaces, 2) unlike other rotary

equal the production of materials remain in that condition designs, no shaft seals and

larger, slower mixers, during mixing and upon discharge, no dead spots or deep recesses

saving floor space. with no densification. Similarly, to harbor contamination,

materials that are dense under ideal 3) multiple drum clean-out doors,

circumstances remain dense during 4) unrestricted access for spraying

mixing and discharge—an added with air, cleaning solutions or

benefit when packaging blended steam, 5) available wash/rinse-in-

material by weight or volume. place spray nozzles, 6) convenient

drain plug, 7) cross ventilation of

one large open area for rapid drying

and 8) ability to visually inspect all

internal surfaces.

Plug gate Retractable

discharge valve intake chute

Large access doors

Trunnion ring Rotating mixing vessel Low power motor Trunnion ring

2