Page 2795 - Flipbook_SolidDesignSoutheast2020

P. 2795

APPLICATIONS FEATURES OPTIONS

I

n High volume mixing of bulk n Gentle mixing with no shear n Mixing drum sealed at both n nternal spray line(s) plumbed

materials with or without liquid n Small footprint and compact ends to prevent product and through the discharge end

additions or coatings size per amount of material atmospheric contamination for liquid additions, coating,

n Processes discharging directly blended n Capacities to 10,000 cu ft/h de-dusting or perfuming

into high volume packaging n Efficient back-flow mixing (283 m /h) at standard n Reversing “discharge weir”

3

lines, silos or railcars action: proprietary mixing flights residence times option allows reversing of drum

n Mixes an exceptionally broad distribute particles dynamically n Uniform blends regardless of rotation for removal of residual

range of bulk chemicals (such with every degree of drum disparate bulk densities and material for changeovers,

as detergents, catalysts, rotation particle sizes cleaning or maintenance

pesticides and fertilizers) and n Highest mechanical efficiency: n Long life with minimal n Finishes meeting USDA, FDA and

bulk foods (such as cereals, lowest power usage per amount maintenance pharmaceutical requirements

powdered drink mixes, snack of material blended n Abrasion-resistant steel, #304

foods and pet foods) n Low power requirements or #316 stainless steel, exotic

n Handles abrasive and corrosive n Lowest labor cost per amount n Externally-mounted seals are alloys, UHMW liners and epoxy

of material blended

products accessed from outside of the coatings for corrosive or

n External “trunnion rollers” mixing drum for fast, easy abrasive conditions

eliminate the need for internal replacement

shafts, shaft seals and n Sanitary designs, construction

associated maintenance and finishes

SPECIFICATIONS n Support structure and guards

available constructed of #304

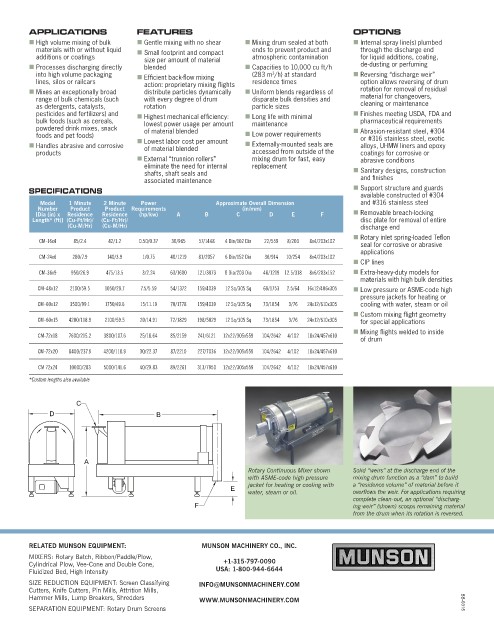

Model 1 Minute 2 Minute Power Approximate Overall Dimension and #316 stainless steel

Number Product Product Requirements (in/mm)

[Dia (in) x Residence Residence (hp/kw) A B C D E F n Removable breach-locking

Length* (ft)] (Cu-Ft/Hr)/ (Cu-Ft/Hr)/ disc plate for removal of entire

(Cu-M/Hr) (Cu-M/Hr) discharge end

n Rotary inlet spring-loaded Teflon

CM-16x4 85/2.4 42/1.2 0.50/0.37 38/965 57/1448 4 Dia/102 Dia 22/559 8/203 8x4/203x102

seal for corrosive or abrasive

applications

CM-24x6 280/7.9 140/3.9 1/0.75 48/1219 81/2057 6 Dia/152 Dia 36/914 10/254 8x4/203x102

n CIP lines

CM-36x9 950/26.9 475/13.5 3/2.24 63/1600 121/3073 8 Dia/203 Dia 48/1219 12.5/318 8x6/203x152 n Extra-heavy-duty models for

materials with high bulk densities

CM-48x12 2100/59.5 1050/29.7 7.5/5.59 54/1372 159/4039 12 Sq/305 Sq 69/1753 2.5/64 16x12/406x305 n Low pressure or ASME-code high

pressure jackets for heating or

CM-60x12 3500/99.1 1750/49.6 15/11.19 70/1778 159/4039 12 Sq/305 Sq 73/1854 3/76 24x12/610x305 cooling with water, steam or oil

n Custom mixing flight geometry

CM-60x15 4200/118.9 2100/59.5 20/14.91 72/1829 198/5029 12 Sq/305 Sq 73/1854 3/76 24x12/610x305 for special applications

n Mixing flights welded to inside

CM-72x18 7600/215.2 3800/107.6 25/18.64 85/2159 241/6121 12x22/305x559 104/2642 4/102 18x24/457x610 of drum

CM-72x20 8400/237.9 4200/118.9 30/22.37 87/2210 227/7036 12x22/305x559 104/2642 4/102 18x24/457x610

CM 72x24 10000/283 5000/141.6 40/29.83 89/2261 313/7950 12x22/305x559 104/2642 4/102 18x24/457x610

*Custom lengths also available

C

D B

A

Rotary Continuous Mixer shown Solid “weirs” at the discharge end of the

with ASME-code high pressure mixing drum function as a “dam” to build

E jacket for heating or cooling with a “residence volume” of material before it

water, steam or oil. overflows the weir. For applications requiring

complete clean-out, an optional “discharg-

F ing weir” (shown) scoops remaining material

from the drum when its rotation is reversed.

RELATED MUNSON EQUIPMENT: MUNSON MACHINERY CO., INC.

MIXERS: Rotary Batch, Ribbon/Paddle/Plow,

Cylindrical Plow, Vee-Cone and Double Cone, +1-315-797-0090

Fluidized Bed, High Intensity USA: 1-800-944-6644

SIZE REDUCTION EQUIPMENT: Screen Classifying INFO@MUNSONMACHINERY.COM

Cutters, Knife Cutters, Pin Mills, Attrition Mills,

Hammer Mills, Lump Breakers, Shredders WWW.MUNSONMACHINERY.COM

SEPARATION EQUIPMENT: Rotary Drum Screens BB-0315